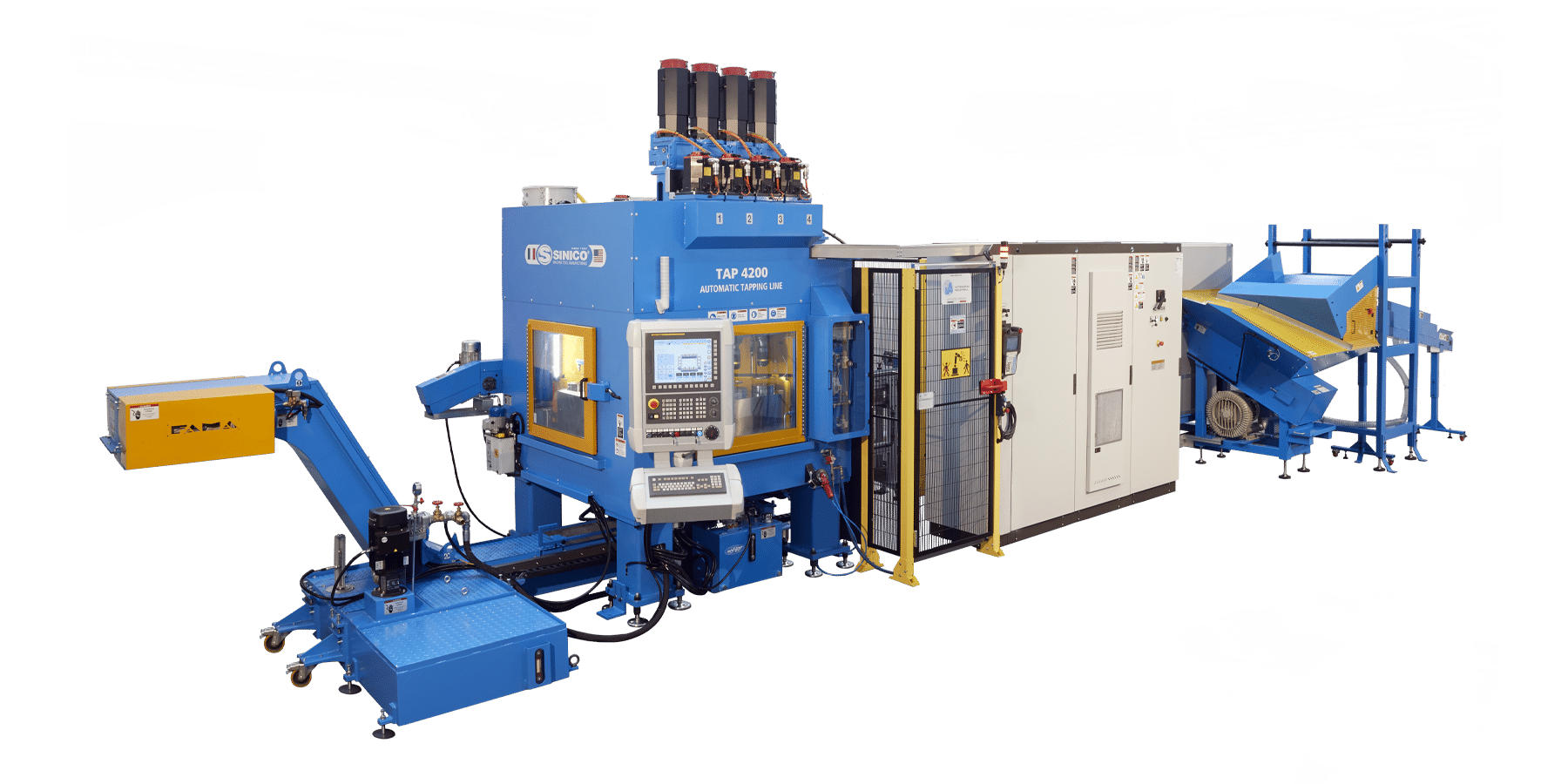

General features

Machine weight

8700 Kg

General dimensions

2.560 x 4.100 x 3.200 mm

CNC

Fanuc

Machine tending

Anthropomorphic robot on request

Max tapping diameter

M36, G 2 ¼”, NPT ¾”, BSF 1 ½”

Max standard machinable lenght

80 mm

Min-Max machinable diameter

20 – 80 mm

Spindle attachment

ISO 50 – HSK 63

Spindle power

14kW, 18.5kW

Number of operating units

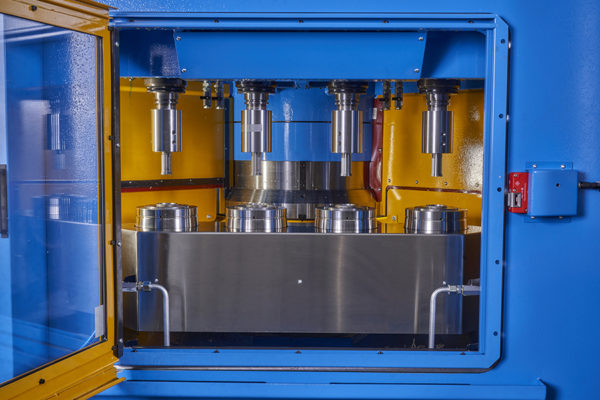

4

Spindle rotation speed

20 – 2.000 rpm

Longitudinal axis stroke “Z”

160 mm

Contact us

Tap 4200

4-operating units vertical-axis rotary transfer machine for machining of cast and cut pieces.

Machine productivity up to 1000 Pcs/hr.

CNC machine with high productivity, designed for the machining of small and medium-sized pieces: 80 mm grip diameter, finished piece length up to 120 mm. Excellent performance for all types of machining. It is able to perform tapping operations.

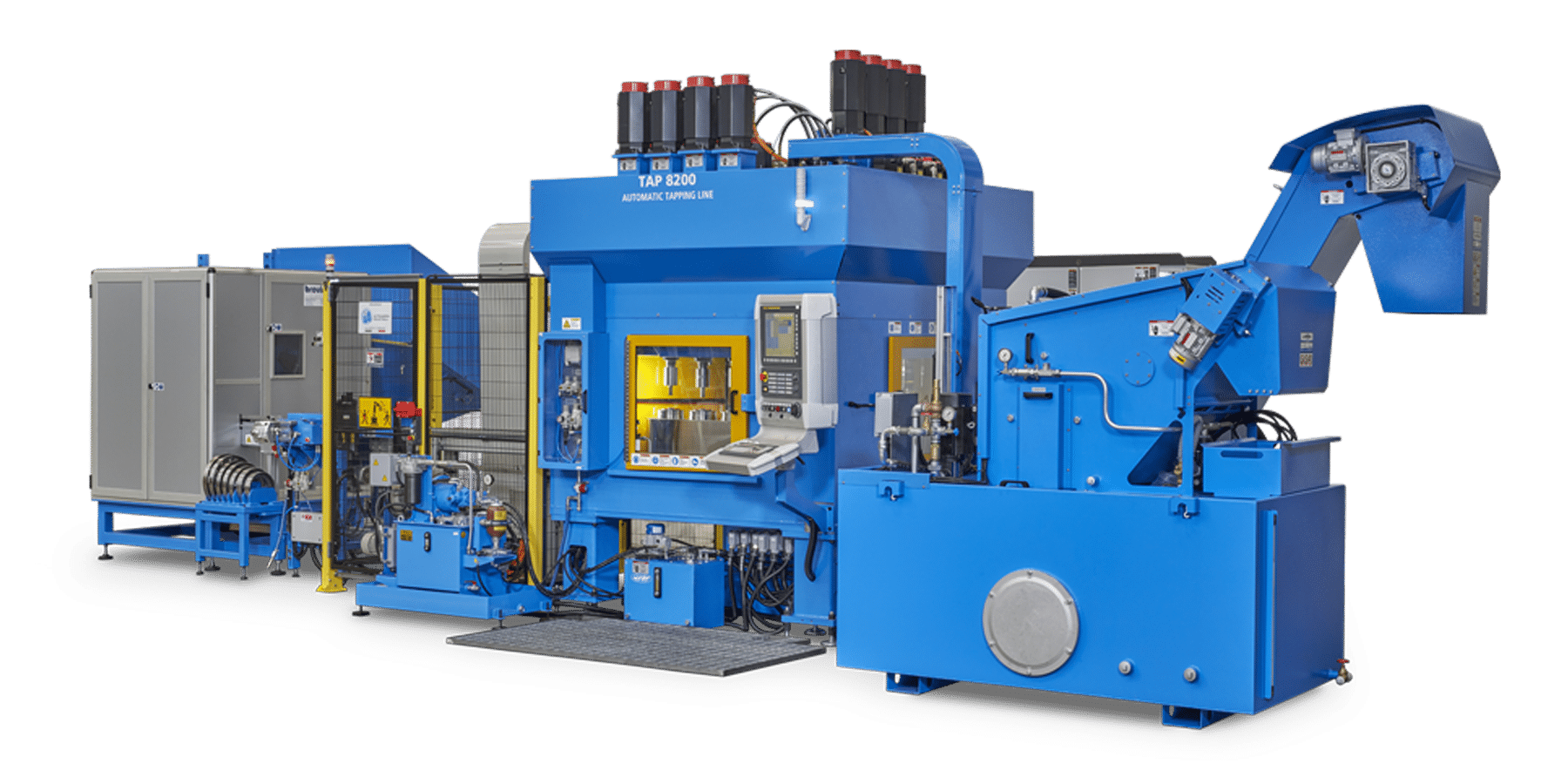

TAP 8200

General features

Machine weight

8700 Kg

General dimensions

2.560 x 4.100 x 3.200 mm

CNC

Fanuc

Machine tending

Anthropomorphic robot on request

Max tapping diameter

M36, G 2 ¼”, NPT ¾”, BSF 1 ½”

Max standard machinable length

80 mm

Min-Max machinable diameter

20 – 80 mm

Spindle attachment

ISO 50 – HSK 63

Spindle power

14kW, 18.5kW

Number of operating units

8

Spindle rotation speed

20 – 2.000 rpm

Longitudinal axis stroke “Z”

160 mm

Contact us

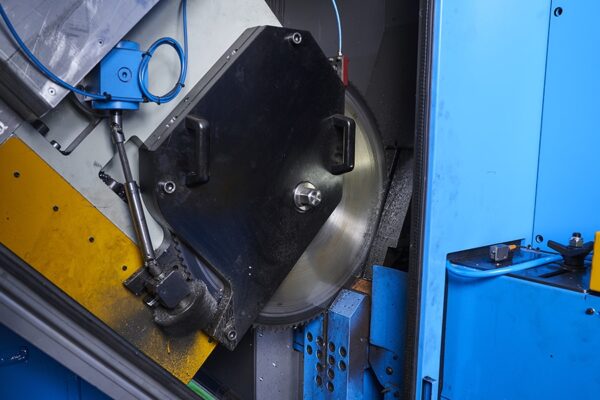

Tap 8200

8-operating units vertical-axis rotary transfer machine for machining of cast and cut pieces.

Machine productivity up to 1000 pieces/hour.

CNC machine with high productivity, designed for the machining of small and medium-sized pieces: 80 mm grip diameter, finished piece length up to 120 mm. Excellent performance for all types of machining. It is able to perform the following processes: Tapping – Boring.

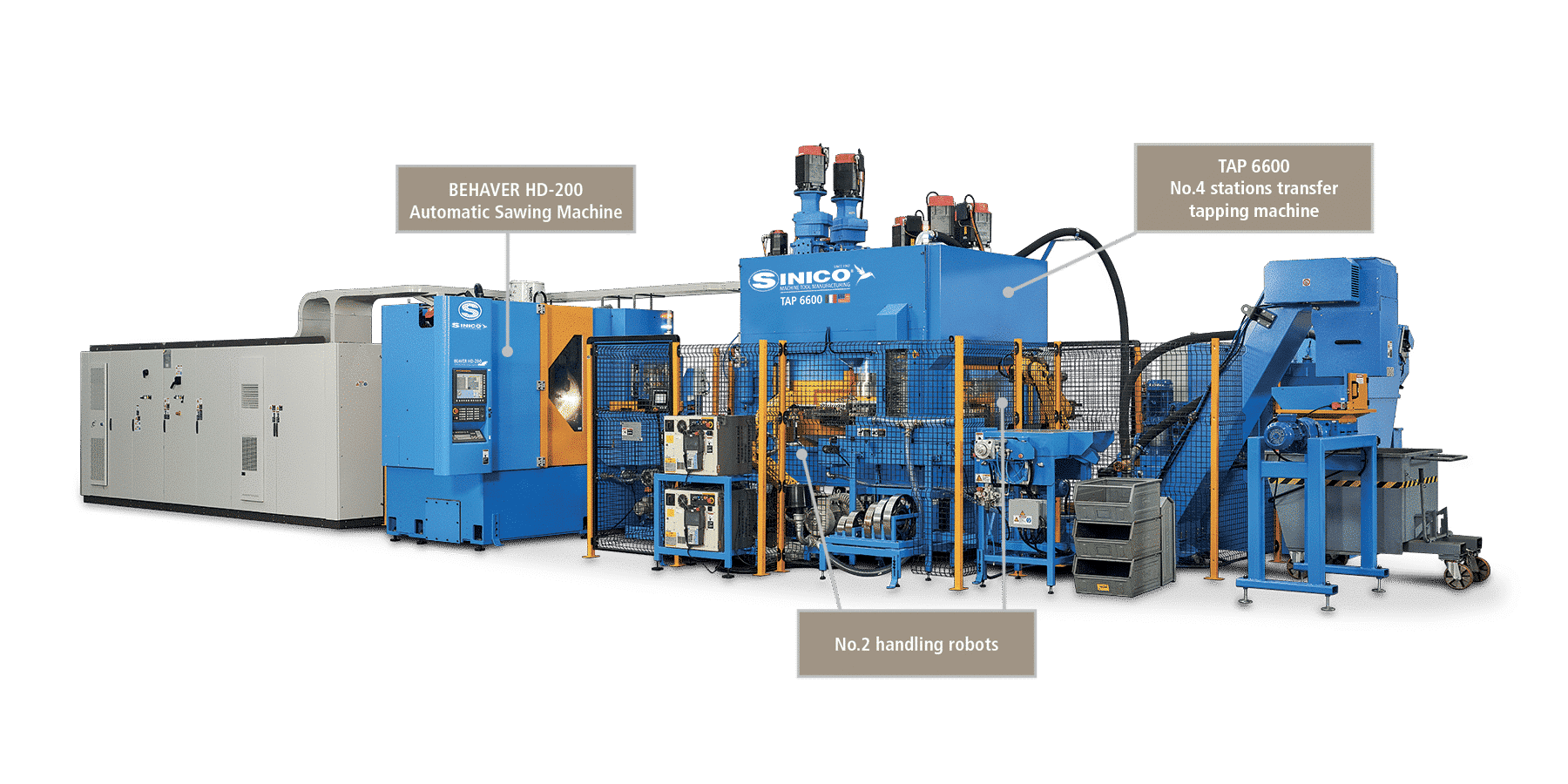

Technical charateristics

All the data below refer to the model shown in the technical data sheet.

- Machine weight: 20000 Kg

- General dimensions: 2.250 x 2.250 x 3.950 mm

- CNC: Fanuc

- Machine tending: Anthropomorphic robot on request

- Max tapping size: 6 “NPSM, 3” NPT, M120, UNC 2 ¾ “

- Standard machinable length: 150 mm

- Min-max machinable diameter: 20 – 200 mm

- Spindle attachment: HSK 80 – HSK 100

- Spindle power: 15kW, 22kW

- Number of operating units: 6

- Min-max spindle rotation speed: 20 – 2.000 rpm

- Longitudinal axis stroke “Z”: 160 mm

Contact usContact us

Pieces machined: Sizes from 2 “to 6”

Produced in-house

Most pieces used to develop the Tap 6600 are produced in our machine shop.

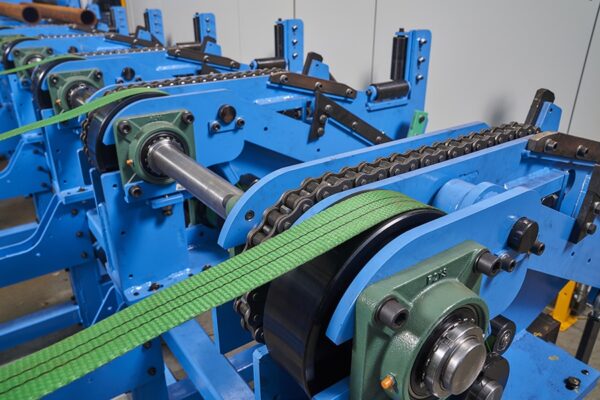

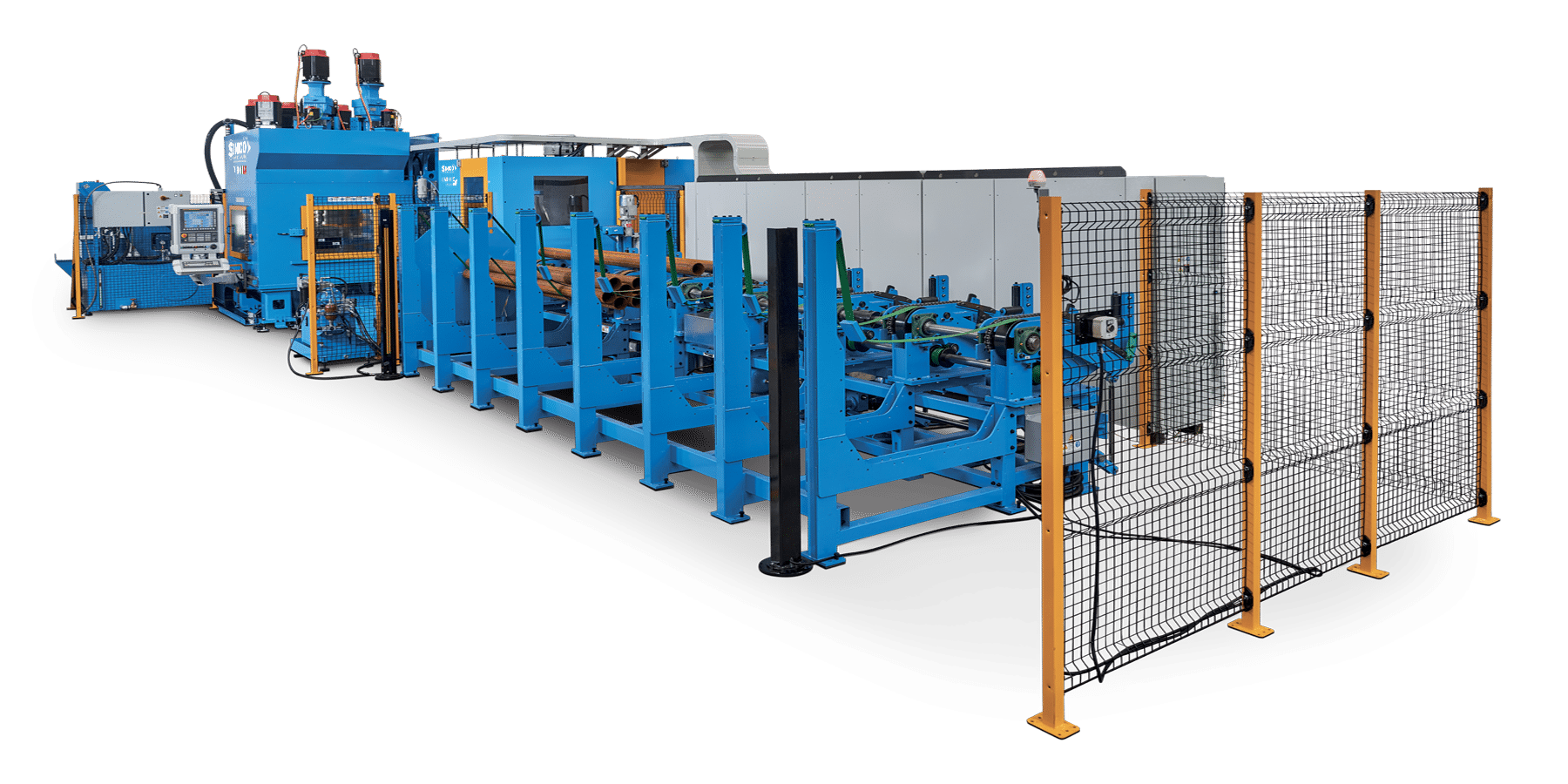

Automated line

From the loader to the automatic cut-off unit, machine tending and offloading of the finished piece, everithing is automated and in-line.

More machining speed

Compared to the machines in the same category, the Tap 6600 reduces machining times