General features

ø Min. of curve DIN2605

ø Max. of curve

No. 2 ISO 50 spindles: 15 kW

CNC longitudinal "Z" axes: no. 2

General dimensions (LxWxH)

Machine weight

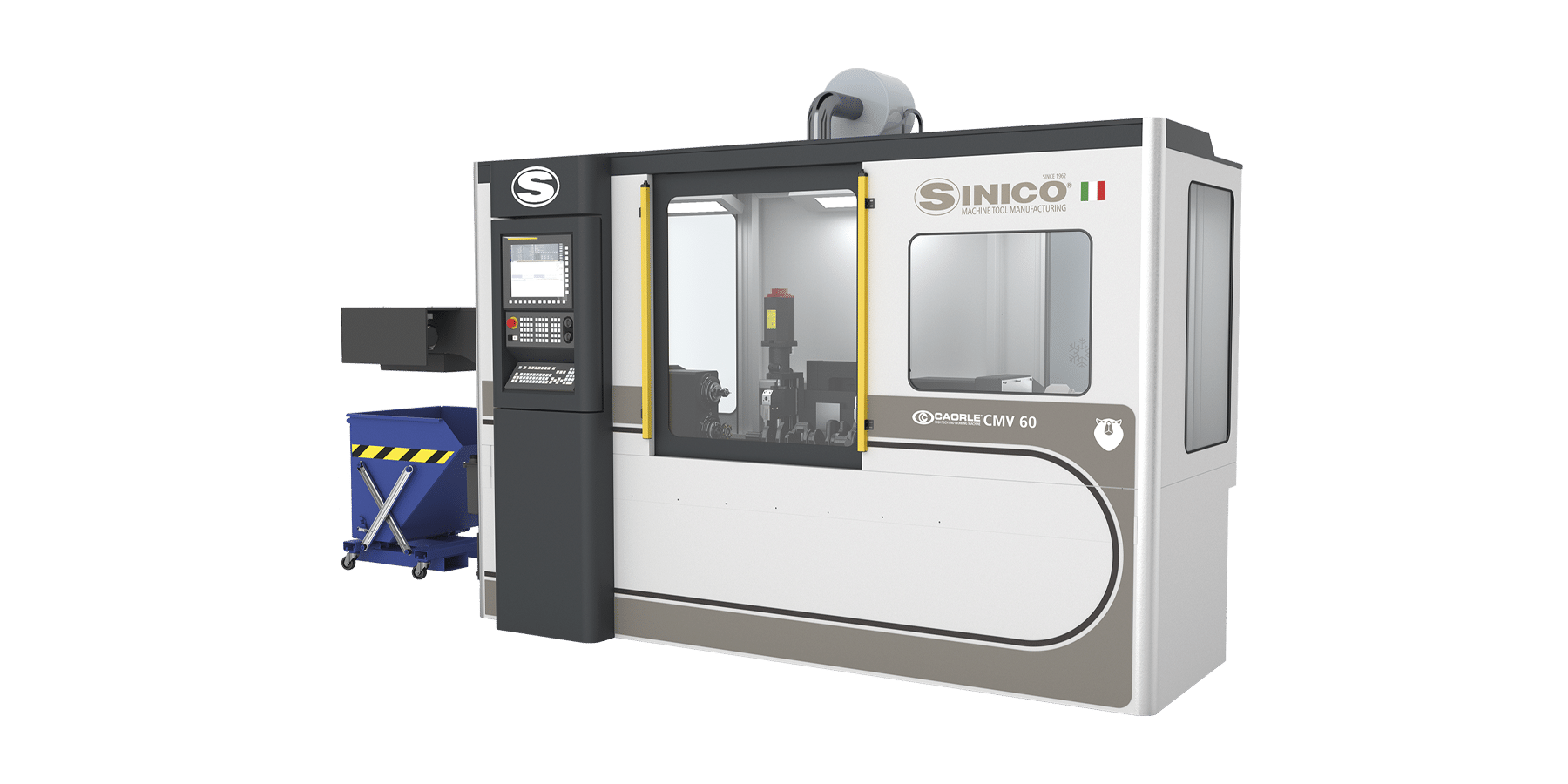

Caorle CMV 60

General features

Max workable length

Min. workable length

Min. clamping diameter

Miax clamping diameter

Min milling diameter

Max milling diameter

Max drilling diameter

Max. drilling depth

Max. tapping capacity

Max tapping depth

Spindle rotation speed min.-max.

Spindle power

Spindle attachment

General dimensions (LxWxH)

Machine weight

Caorle CMV 60

Versatile and Powerful.

The CMV60 model trimming center is a machine designed and built in various models that allows the machining of the ends of bars, tubes, molded parts and forging by means of 2 opposing heads each having a maximum of 3 spindles:

- a milling spindle

- a centering / drilling spindle

- a tapping spindle

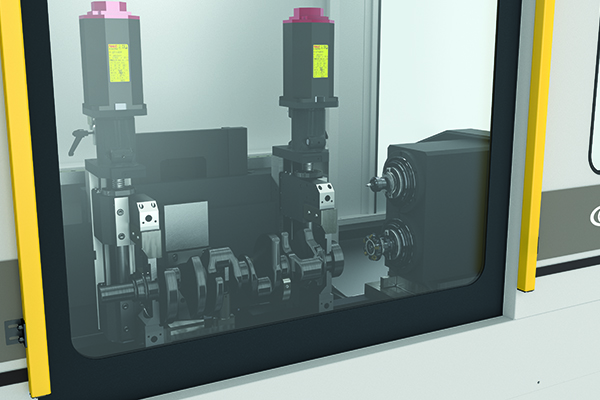

Caorle MC640

General features

Transverse axis stroke "X": 325 mm

Vertical axis stroke "Y": 325 mm

Longitudinal axis stroke "Z": 600 mm

Spindle rotation speed min.-max.

Spindle power

Spindle attachment

Machinable diameter min.-max.

Min. workable length: 20 mm

Machinable length on request

Min-max tapping size: M5 - M24

Number of tools

General dimensions (LxWxH)

Machine weight

Installed power

CNC

Caorle MC640

Versatile and Powerful.

Machining centre for machining at the ends, equipped with 2 opposing 3-axis operating units. Numerical control machine capable of simultaneously performing end machining on pipes or bars. Machine designed to be enslaved by an automatic loading system

It is able to perform operations of:

- bezel

- facing

- drilling in axis and off axis

- deep drilling in axis and off axis

- thread

- turning with static piece

- boring

- milling

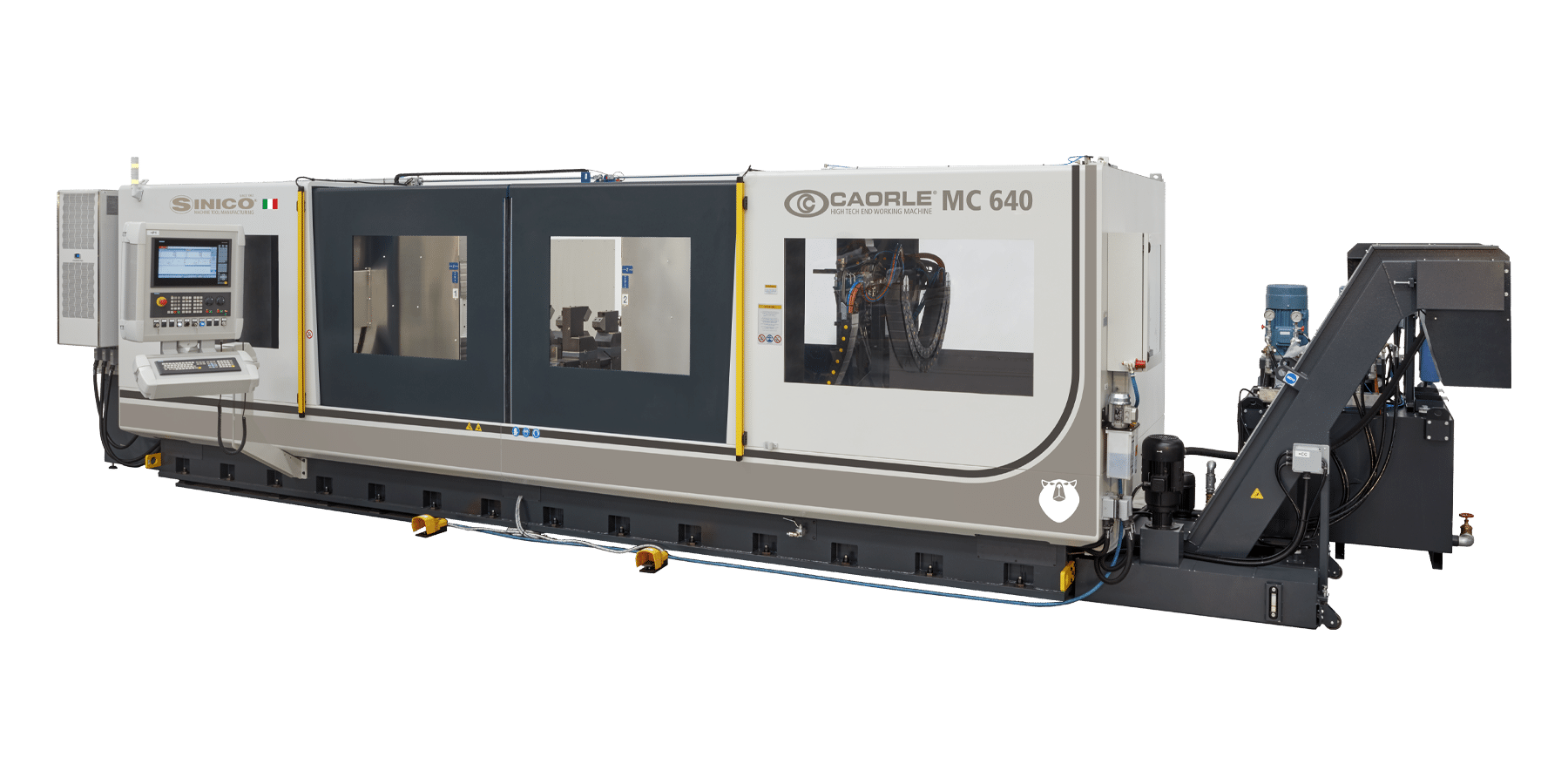

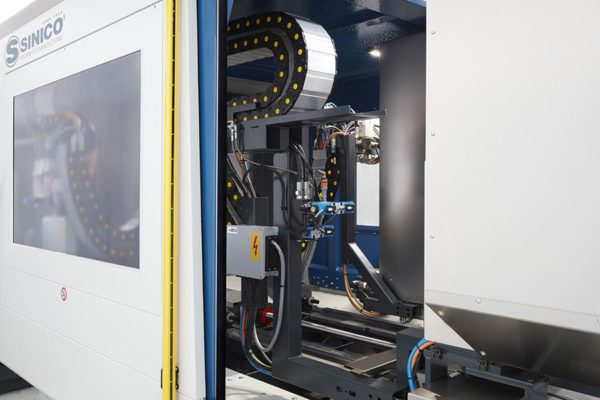

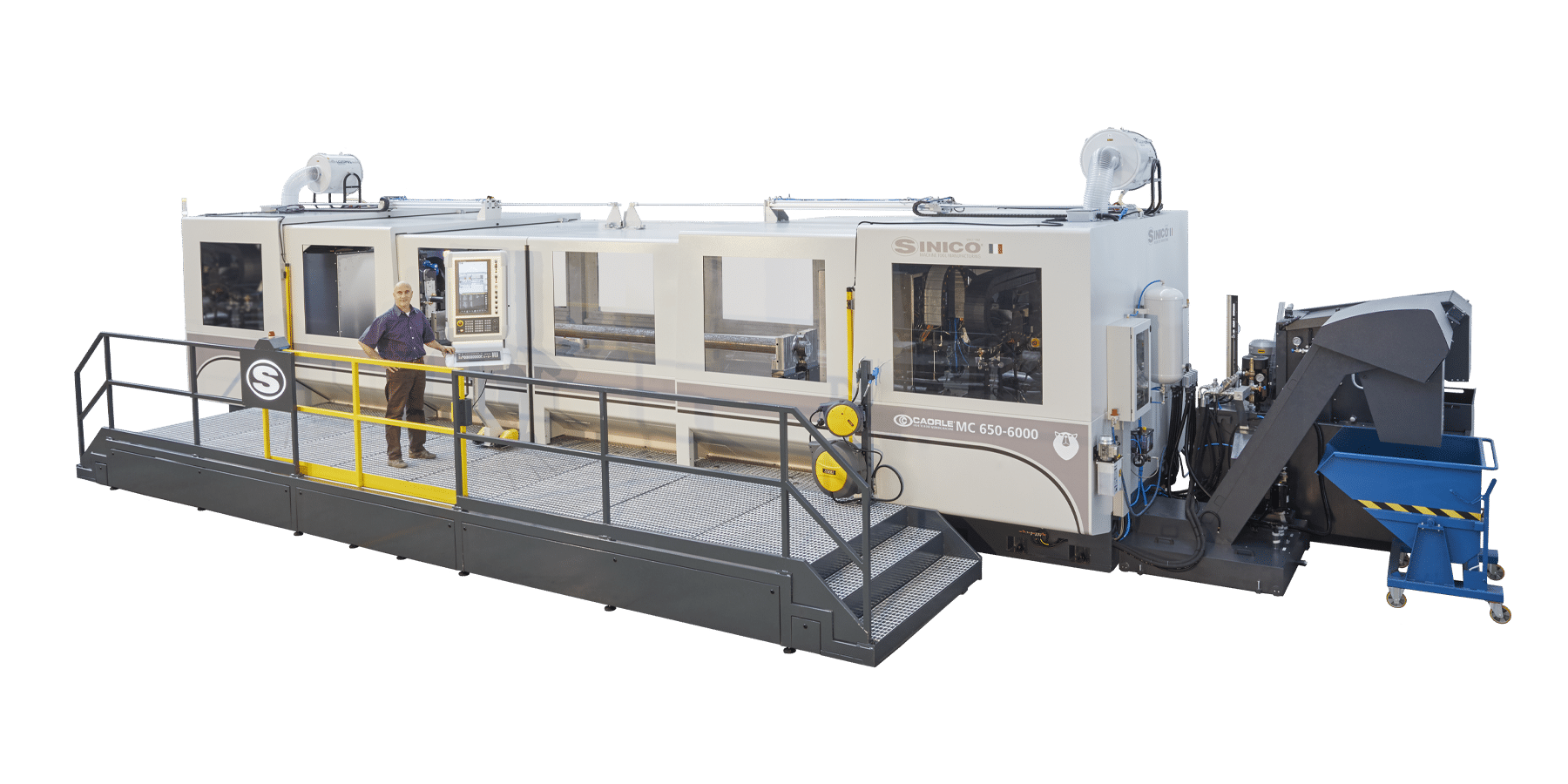

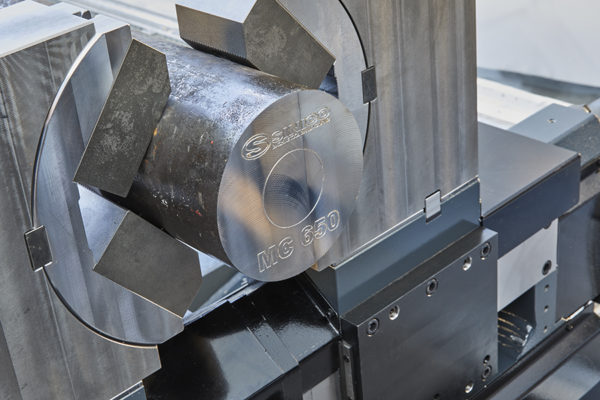

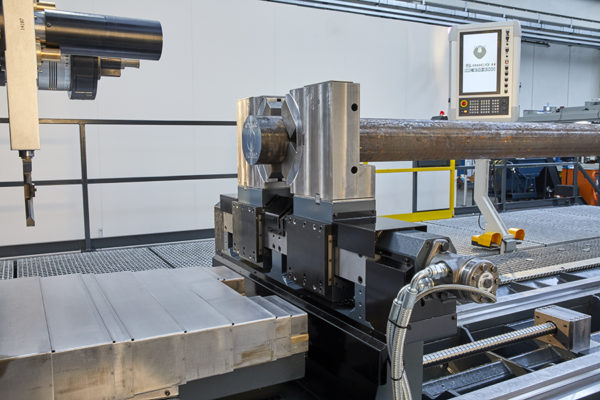

Caorle MC650

General features

Machine weight

Installed power

General dimensions (LxWxH)

Number of tools

Transverse axis stroke "X": 325 mm

Vertical axis stroke "Y": 325 mm

Longitudinal axis stroke "Z": 600 mm

Spindle rotation speed min.-max.

Spindle power

Spindle attachment

Min. workable length: 20 mm

Machinable diameter min.-max.

Machine capacity, in length

Max tapping size: M33

CNC

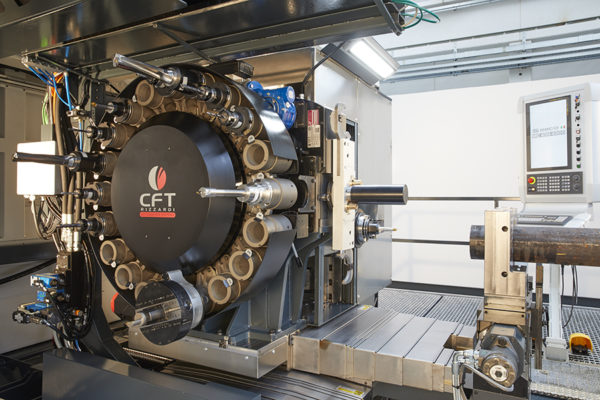

Caorle MC650

Versatile and Powerful.

Two ISO 50 spindles end working machine, equipped with 3 + 3 CNC axis for heavy and precise processing

Horizontal machining center for machining at the ends, equipped with 2 opposing 3-axis operating units.

Numerical control machine capable of simultaneously performing end machining on pipes or bars.

Machine designed to be enslaved by an automatic loading system

It is able to perform operations of:

- bezel

- facing

- drilling in axis and off axis

- deep drilling in axis and off axis

- thread

- turning with static piece

- boring

- milling

- profiling

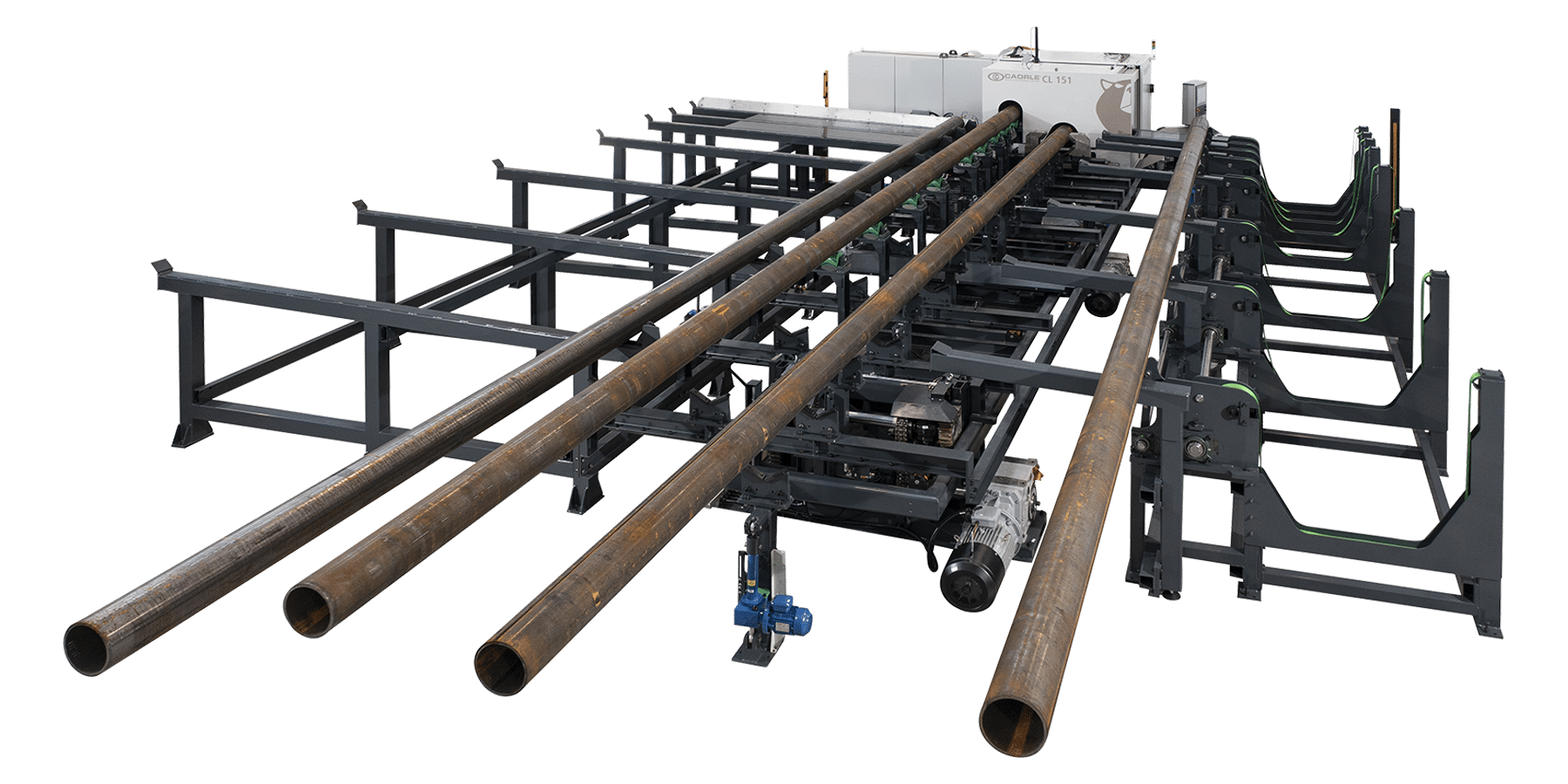

Caorle CL151

General features

Machine weight

Installed power

Longitudinal axis stroke "Z": 600 mm

Longitudinal axis stroke "Z": 5890 mm

Spindle power: 18.5 Kw

Machinable diameter min.-max.

Machinable length min. - max.

CNC

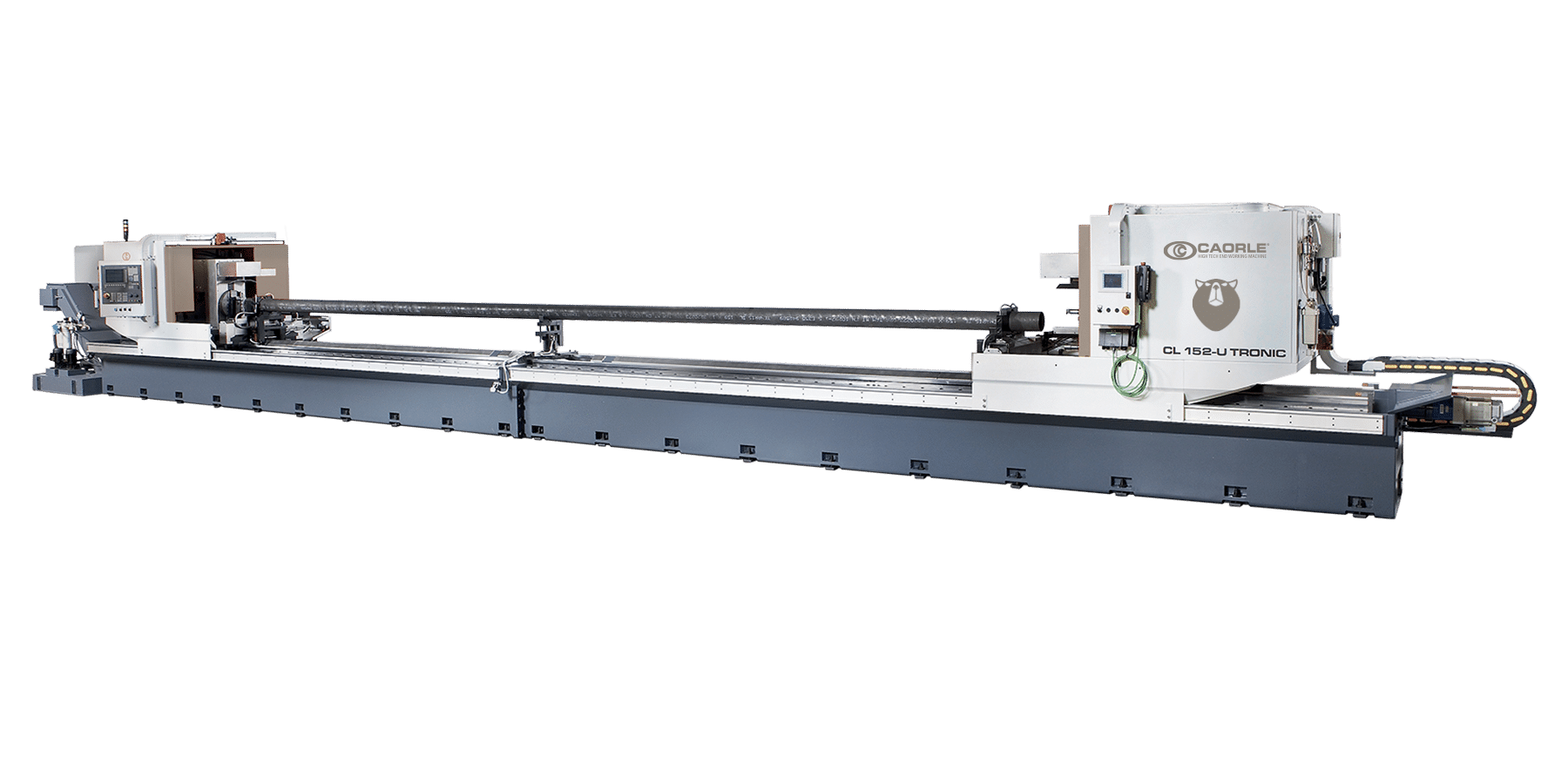

Caorle CL152 Utronic

General features

Longitudinal axis stroke "Z": 600 mm

Spindle rotation speed min.-max.

Spindle power

Machinable diameter min.-max.

Machinable length min. - max.

General dimensions (LxWxH)

Machine weight

CNC

Caorle CL152

Versatile and Powerful.

Centro di lavoro con due teste a movimento radiale CN

contrapposte per lavorazioni alle estremità.

E’ in grado di eseguire operazioni di:

- smussatura

- sfacciatura

- foratura in asse e fuori asse

- foratura profonda in asse e fuori asse

- filettatura

- tornitura con pezzo statico

- barenatura

- fresatura