Sinico MTM US

For quick and professional service.

Since 2016, Sinico has been present in the U.S. territory on the outskirts of Cleveland "Sinico US," an important reference point for U.S. customers who can count on close service, installation and spare parts in extremely short time.

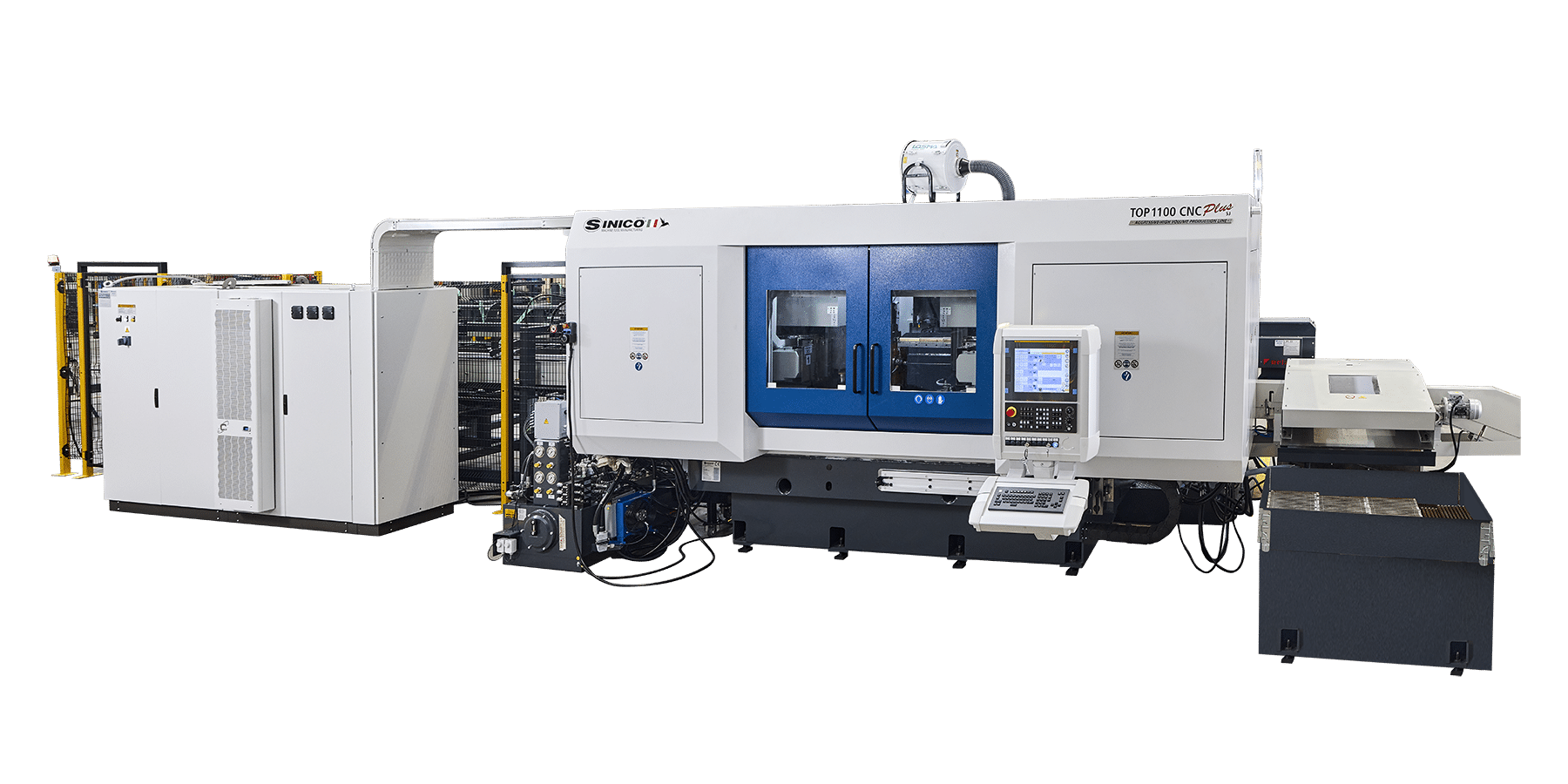

Top 1100 CNC pLus

Machine productivity up to 2600 pieces / hour, bar diameter from 6 to 95mm, finished piece length up to 400mm.

It is capable of performing the following operations:

Chamfering – Facing – Drilling – Threading – Turning with static workpiece – Boring – Forming – Marking

Top 1100 CNC Plus SJ

Machine productivity up to 2600 pieces / hour, bar diameter from 10 to 115 mm, finished piece length up to 1050 mm.

It is capable of performing the following operations:

Chamfering – Facing – Drilling – Threading – Turning with static workpiece – Boring – Forming – Marking – Milling

Top 1100 R2 CNC

Machine productivity up to 2750 pieces / hour, bar diameter from 4 to 55 mm, finished piece length up to 200mm.

Chamfering – Facing – Drilling – Threading – Turning with static workpiece – Boring

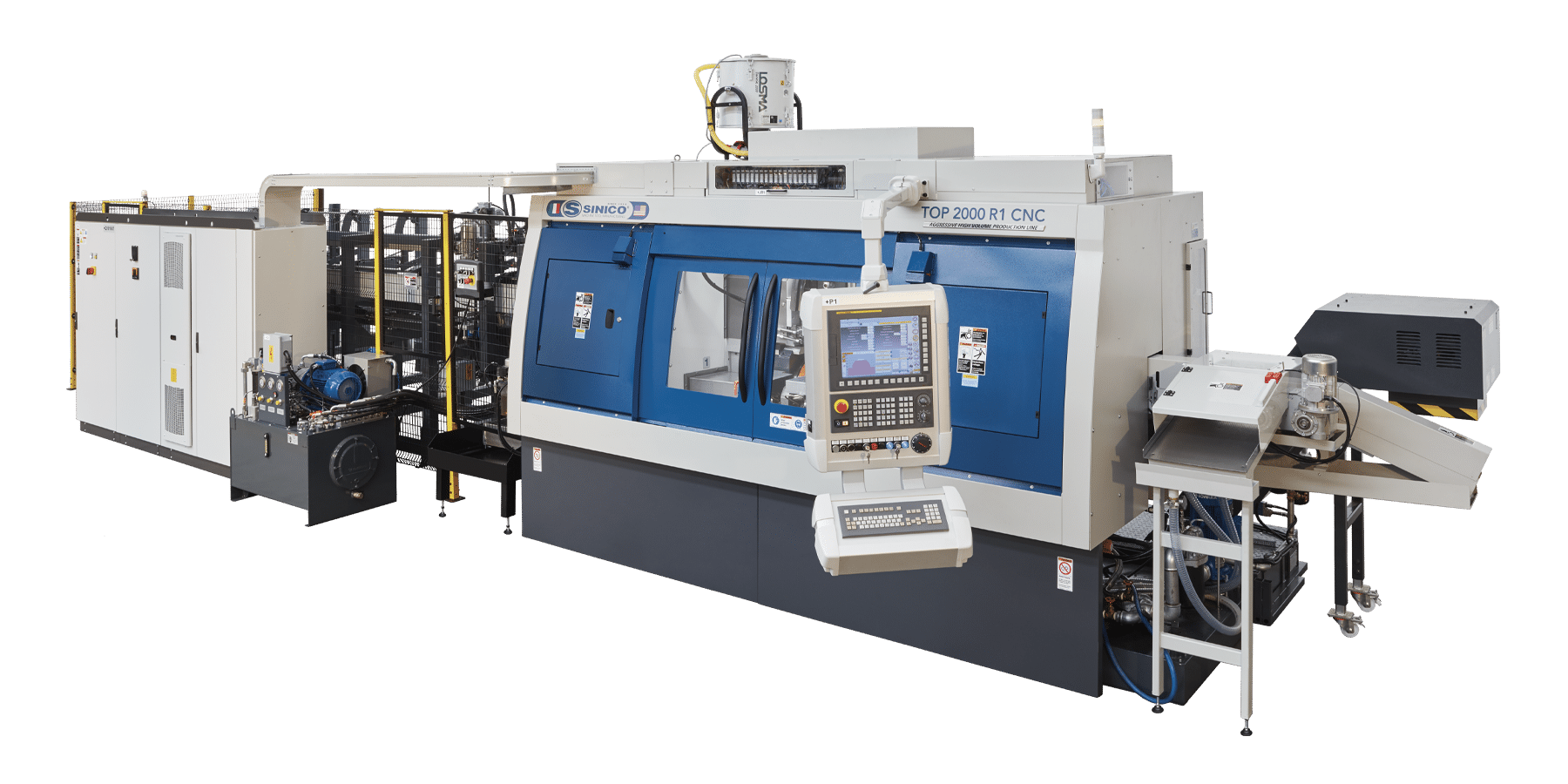

Top 2000 R1 CNC

Machine productivity up to 2500 pieces / hour, bar diameter from 6 to 110mm, finished piece length up to 700mm.

It is capable of performing the following operations:

Chamfering – Facing – Longitudinal and transverse drilling – Threading – Turning with static workpiece – Turning with rotating workpiece – Boring – Forming – Marking – Milling

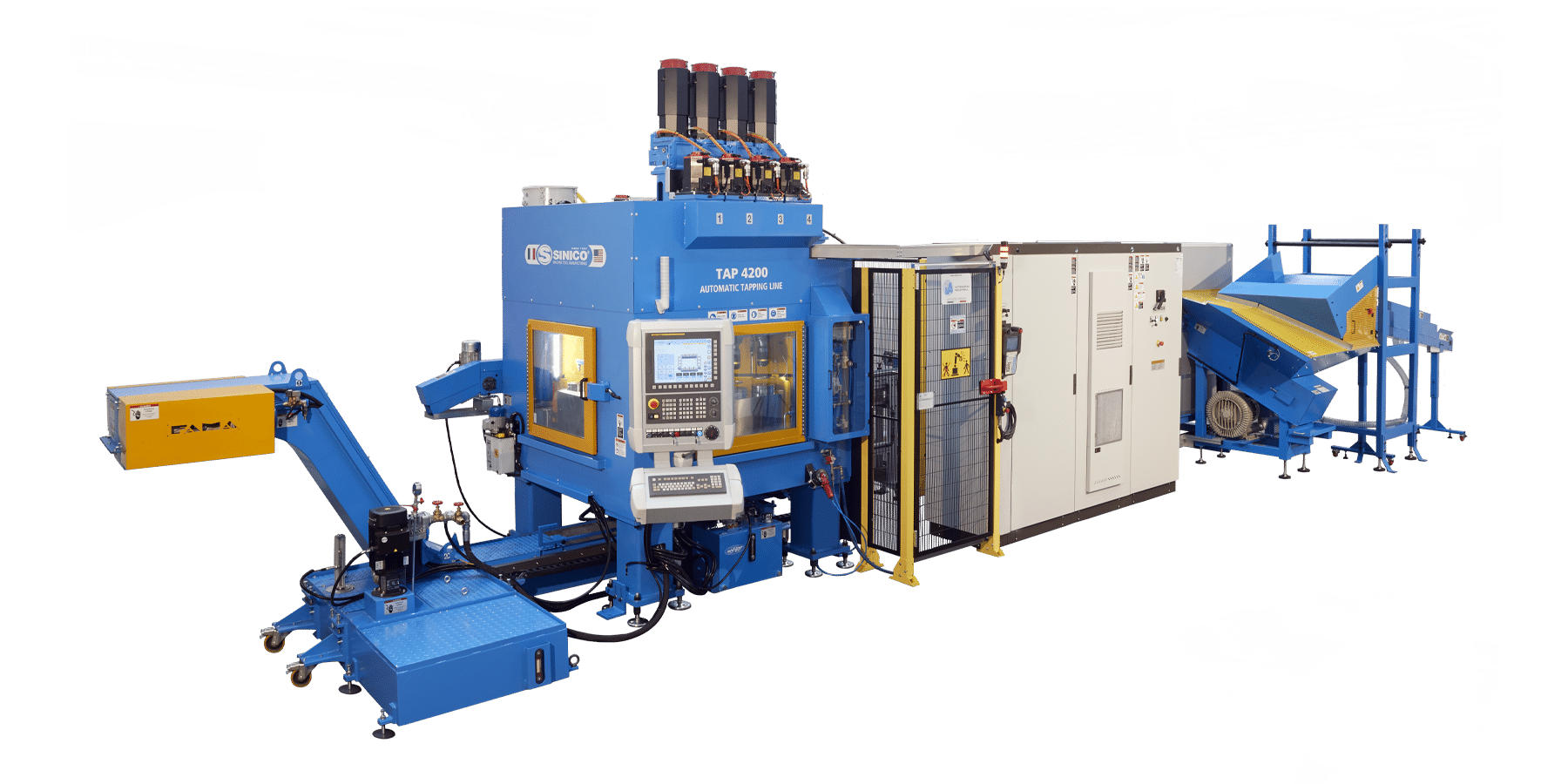

Tap 4200

Machine productivity up to 1000 pieces / hour, gripping diameter up to 80mm, finished piece length up to 120mm.

Performs tapping operations.

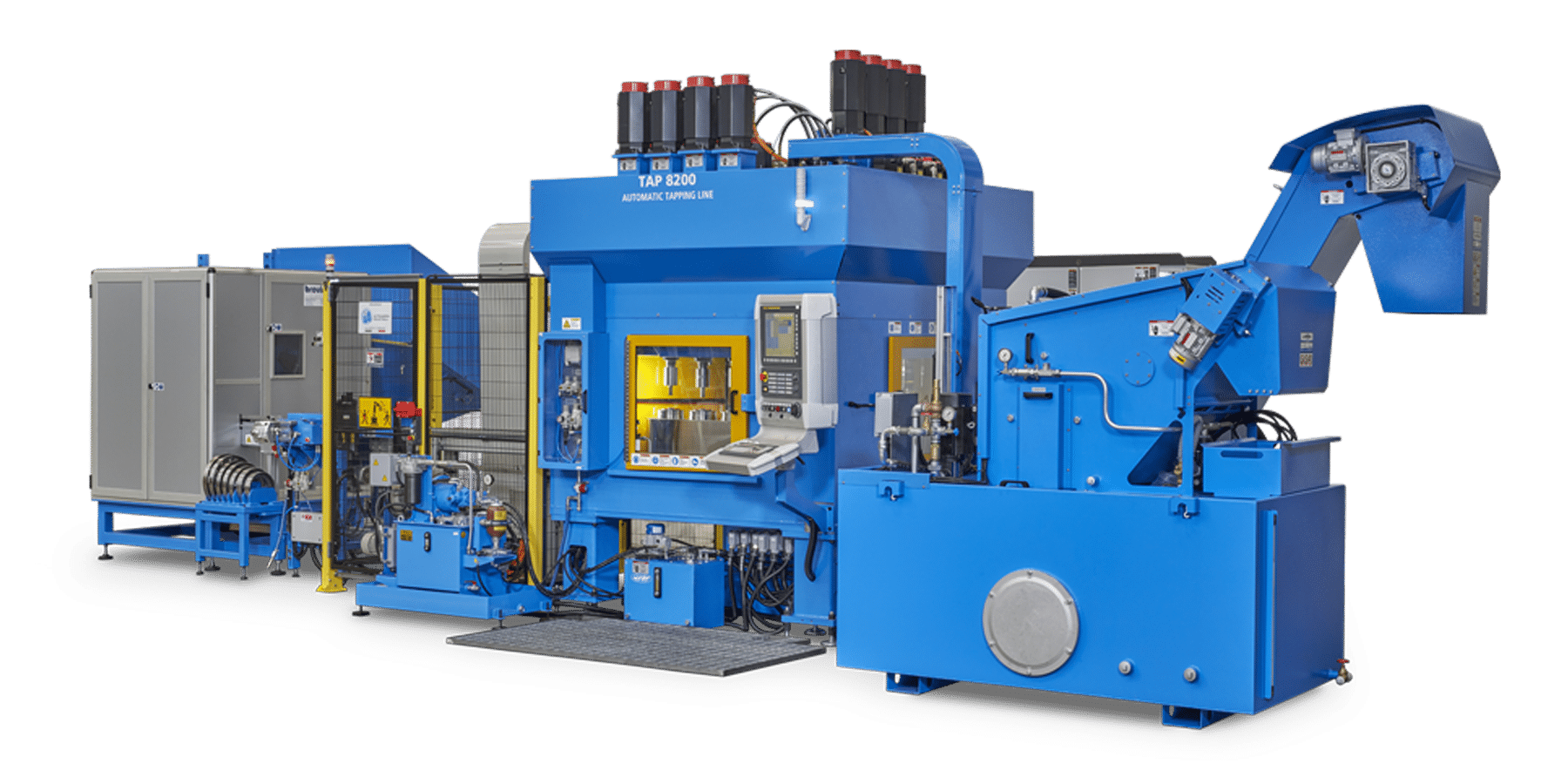

Tap 8200

Machine productivity up to 1000 pieces / hour, gripping diameter up to 80mm, finished piece length up to 120mm.

Performs tapping and boring operations.

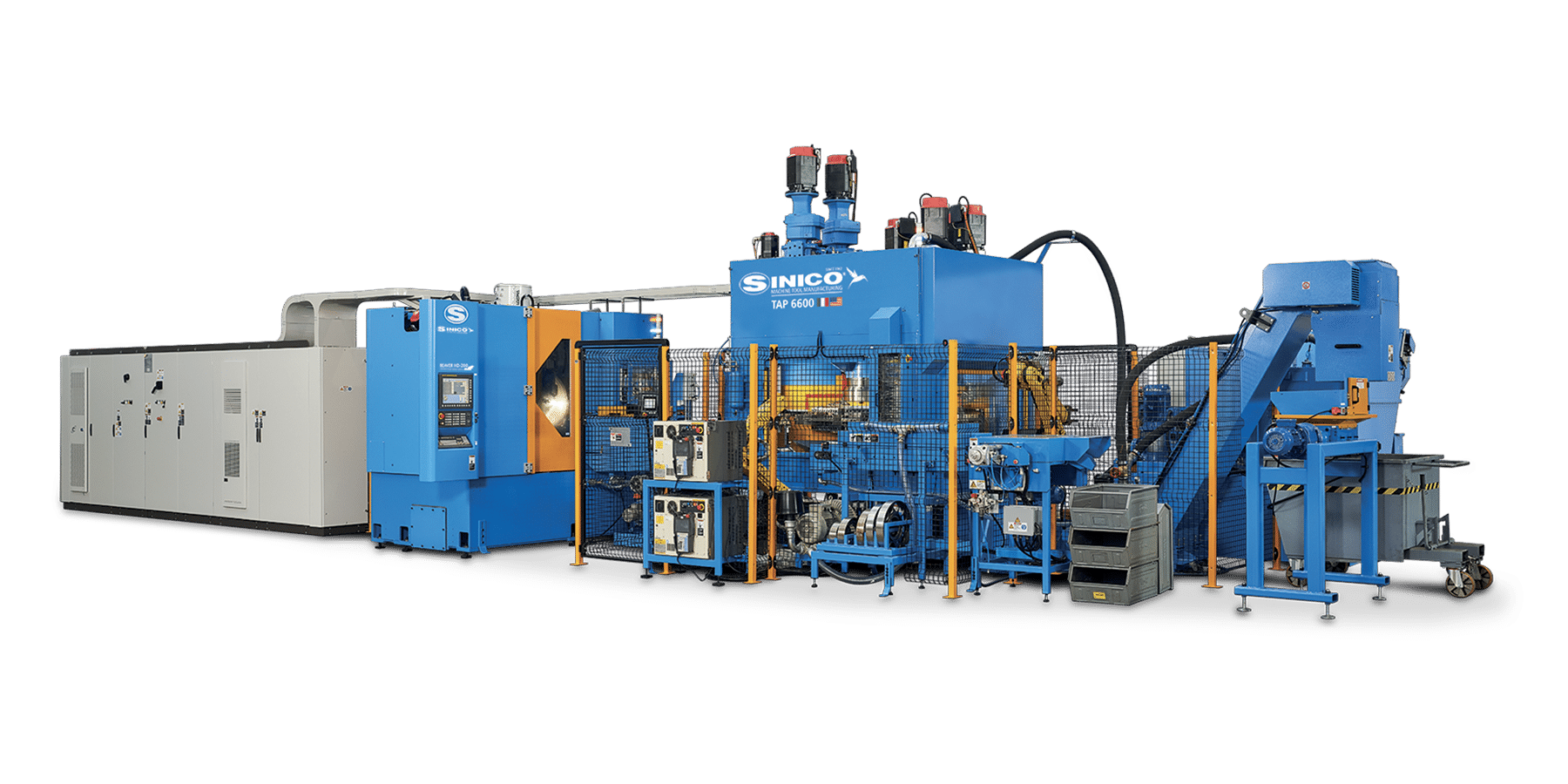

Tap 6600

Machine productivity up to 1000 parts/hour, gripping diameter up to 190 mm,

finished part length up to 150 mm.

Performs tapping, boring, threading operations.

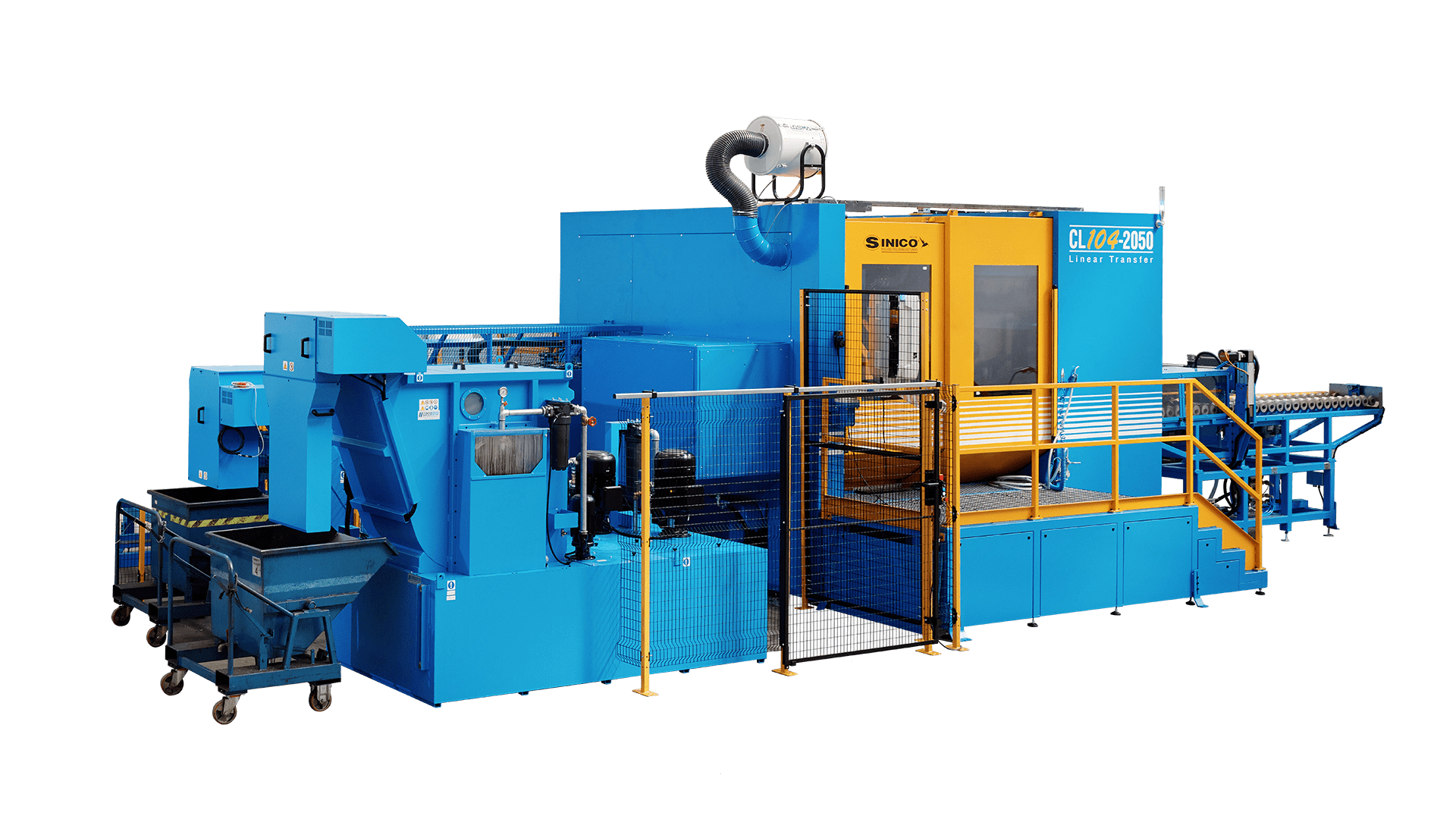

CL 104-2050 Linear Transfer

Machine productivity up to 600 parts/hour, gripping diameter up to 10-115mm, finished part length up to 300-2050mm.

Performs operations of Chamfering – Facing – Drilling – Threading – Turning with static workpiece – Boring – Forming –

Marking – Milling.

CL 90

CNC machining center with 90° unit for curved fittings machining equipped with automatic system for workpiece loading/unloading.

It is capable of performing the following operations:

Heading – External chamfering

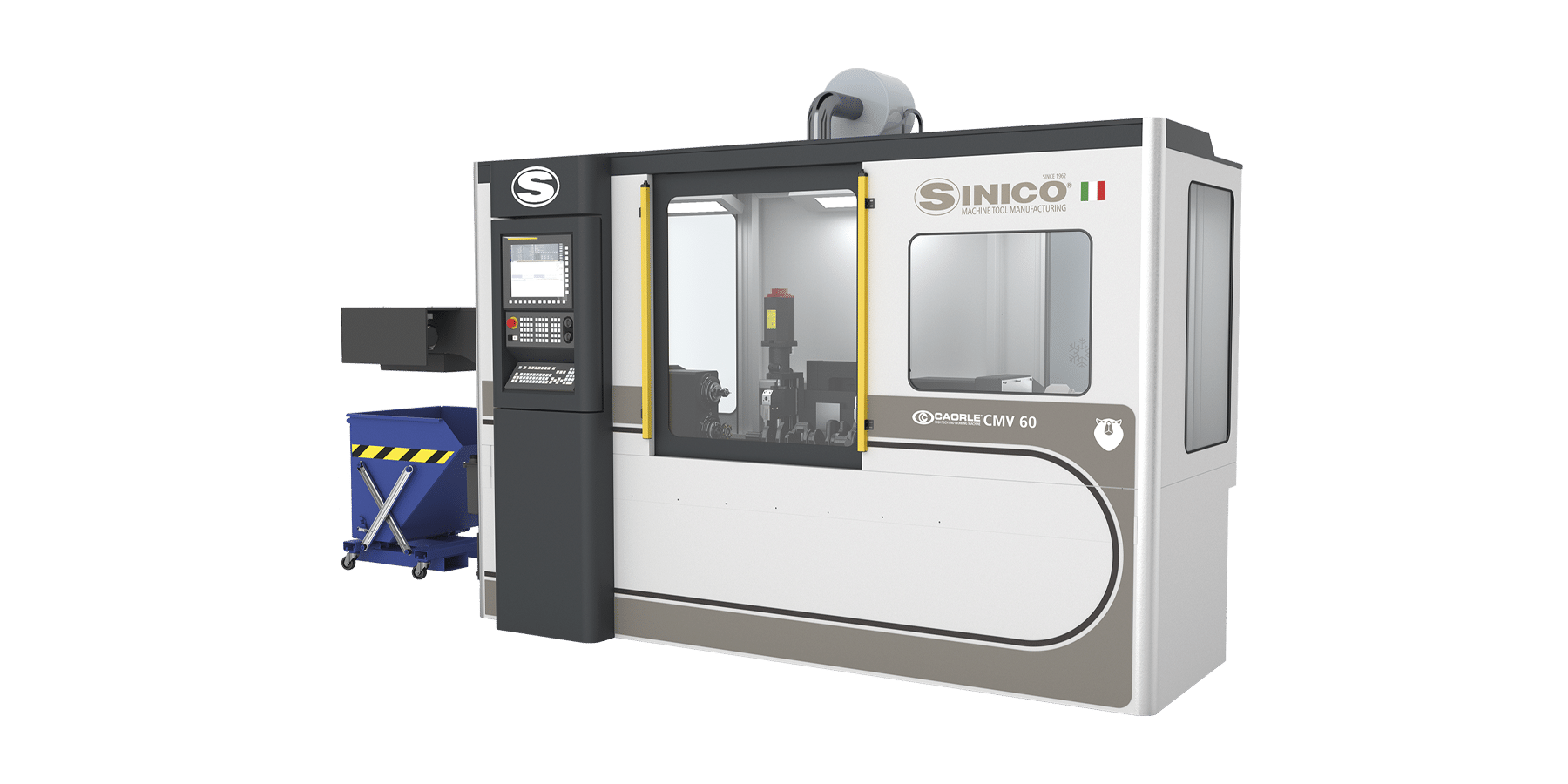

CMV 60

Machining of the ends of bars, tubes, molded and forged by means of 2 opposing heads each having a maximum of 3 spindles.

It is capable of performing the following operations:

Milling – Centering – Drilling – Tapping

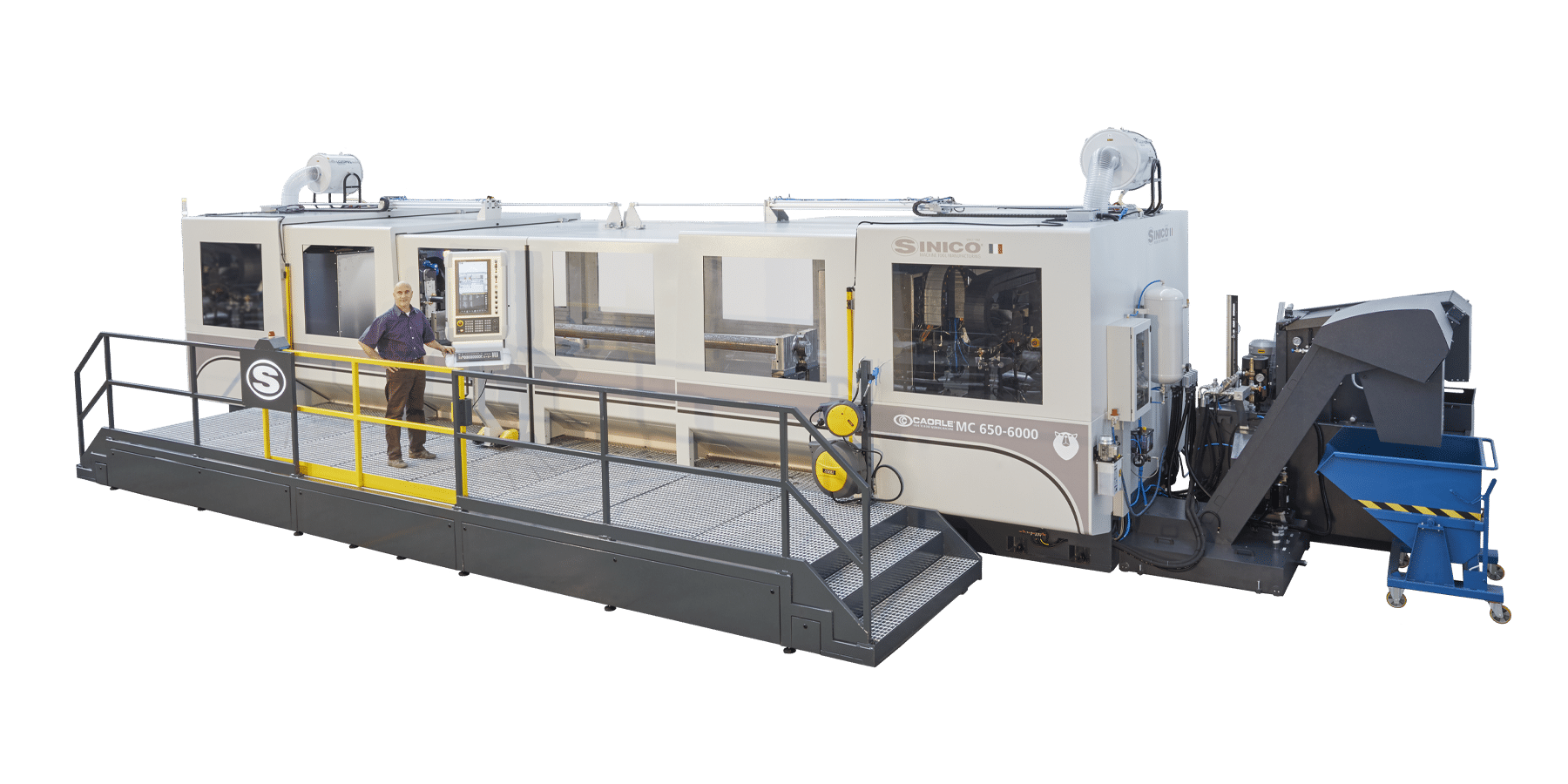

Mc 650

ISO finishing machine equipped with 50 spindles and 3 + 3 CNC axes for heavy and precise machining.

It is capable of performing the following operations:

Chamfering – Facing – Axial and off-axis drilling – Deep axial and off-axis drilling – Threading – Turning with static workpiece – Boring – Milling – Profiling

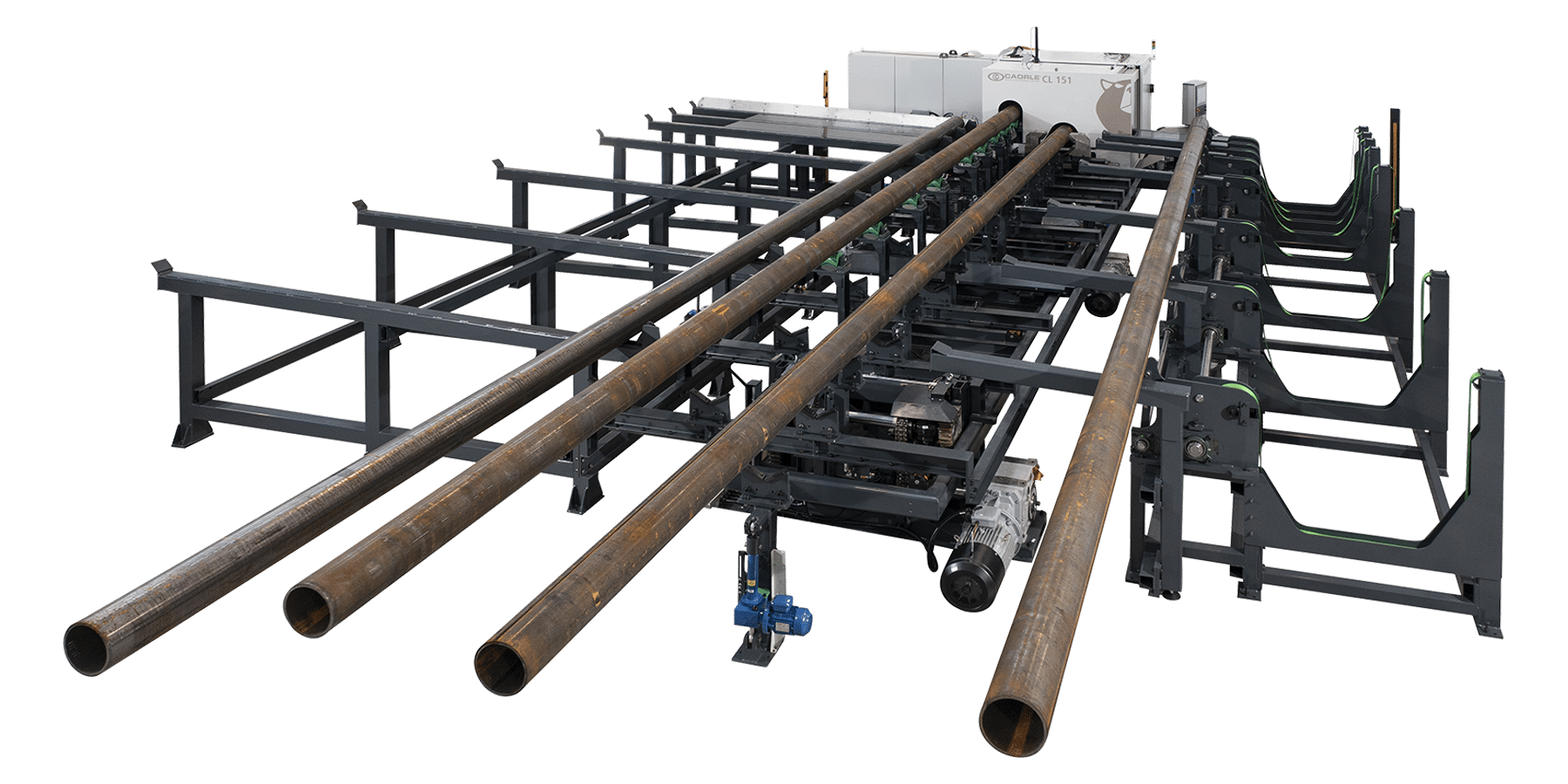

CL 151 Utronic

End processing machine, equipped with bar loader / transfer device with pilgrim’s pitch for heavy bars.

It is capable of performing the following operations:

Threading – Tapping – Boring – Milling

SB70-S robot island

for unloading and palletising finished parts, which can be combined with Sinico’s TOP and TAP lines with a maximum lifting capacity of 70 kg for this model.

RB70-S

Equipped with a Fanuc robot and electronics with a magnetic gripper, it is able to handle the workpiece from pick-up to storage on the crate and back in a cycle time of 12’, can handle different lengths of workpieces in the same process through automatic adjustment, and can recognise the different dimensions of the crates to be loaded.

It can also be equipped with a workpiece oiling system.

It is fully protected in its entire perimeter by a safety barrier and is equipped with full CE integration.

The overall dimensions of the entire structure are (WxLxH) 3500x4000x2500 mm.

Do you want more information on the products offered by our company?

Operating sqm

10

Team Member

90

Kg Products

300

Pieces per day

1000

We are constantly evolving

Our News