Tapping is the machining process by which female threads are created inside a hole or pipe by the use of a male. As we have seen in the article about threading, the fastening obtained by screwing between screw and nut is very popular due to its resistance to high pressure and corrosion. Tapping creates the internal structure that allows this type of joint.

Tapping tool

The tool used for tapping, as we have said, is the tap, which has a cutting helix capable of cutting through the metal and thus creating the internal thread. There are various types of taps and their choice depends mainly on the type of material to be machined, the size and shape of thread. A further element influencing the decision is the type used to perform the machining, in fact in manual tapping three taps are required, while machines only need one that performs all functions.

Hand made tapping

Three different types of tools are required in hand tapping: a roughing tool, an intermediate tool and a finishing tool. They have different ridges and insert diameters and are used in sequence to progressively remove material and create the thread. An important aspect that must be considered in hand tapping is the lubricant. In addition to choosing the right type, attention must also be paid to the right amount to use in order to achieve a good end result.

Machine tapping

If, on the other hand, it is a machine tool that performs tapping, only one type of tap is used for the entire operation. In fact, machines like these are able to impress sufficient force and stability to remove the right amount of material with just one tool. Machine tools are essential for high volume production. Thanks to automation, they are able to have greater control over the machining process and ensure repeatability of execution.

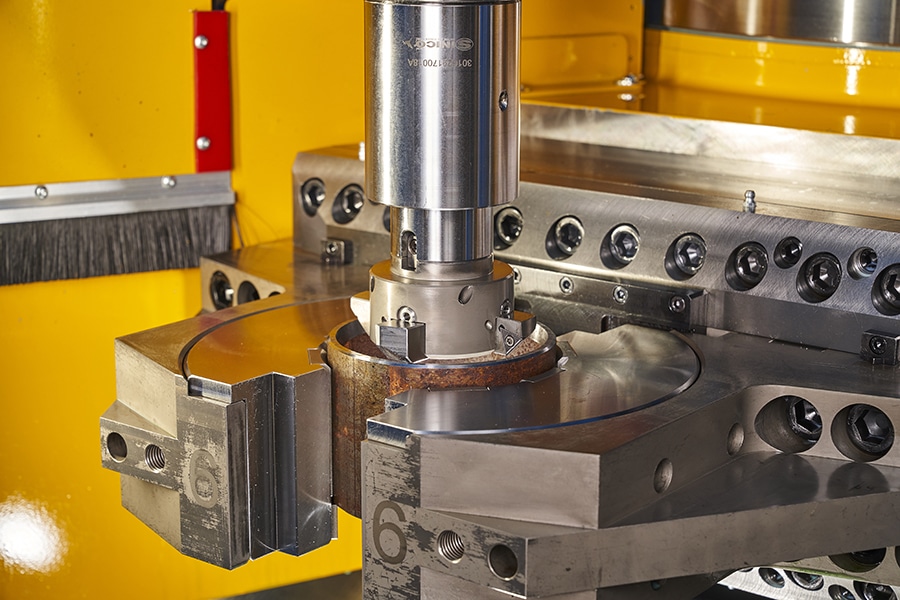

Sinico machines

Sinico machines are used for the production of various components that require several mechanical operations such as chamfering, boring and turning. However, the operations most requested by our customers are tapping and threading. For the latter, specific analyses have been carried out and important partnerships with key suppliers have been established. These efforts led in 2018 to the creation of a new line of machines specialising in tapping: TAP.

This family of vertical table transfer machines can perform automated tapping to a depth of up to 150 mm on workpieces up to 200 mm in diameter. High-quality components such as the Fanuc CNC allowed us to design a line capable of minimising cycle time by producing up to 1000 parts per hour.

There are three Tap Line models available and they are designed for specific production ranges. In each case, each Sinico machine is configured according to the customer’s specific requirements to provide the most efficient solution. The Tap lines are also very versatile, being able to process either pre-cut, forged or stamped pieces or perform the cutting operation independently with a special external unit.

If you are a manufacturer of internally or externallythreaded bushings or fittings, do not wait to contact us, together we will find the best solution for your production.