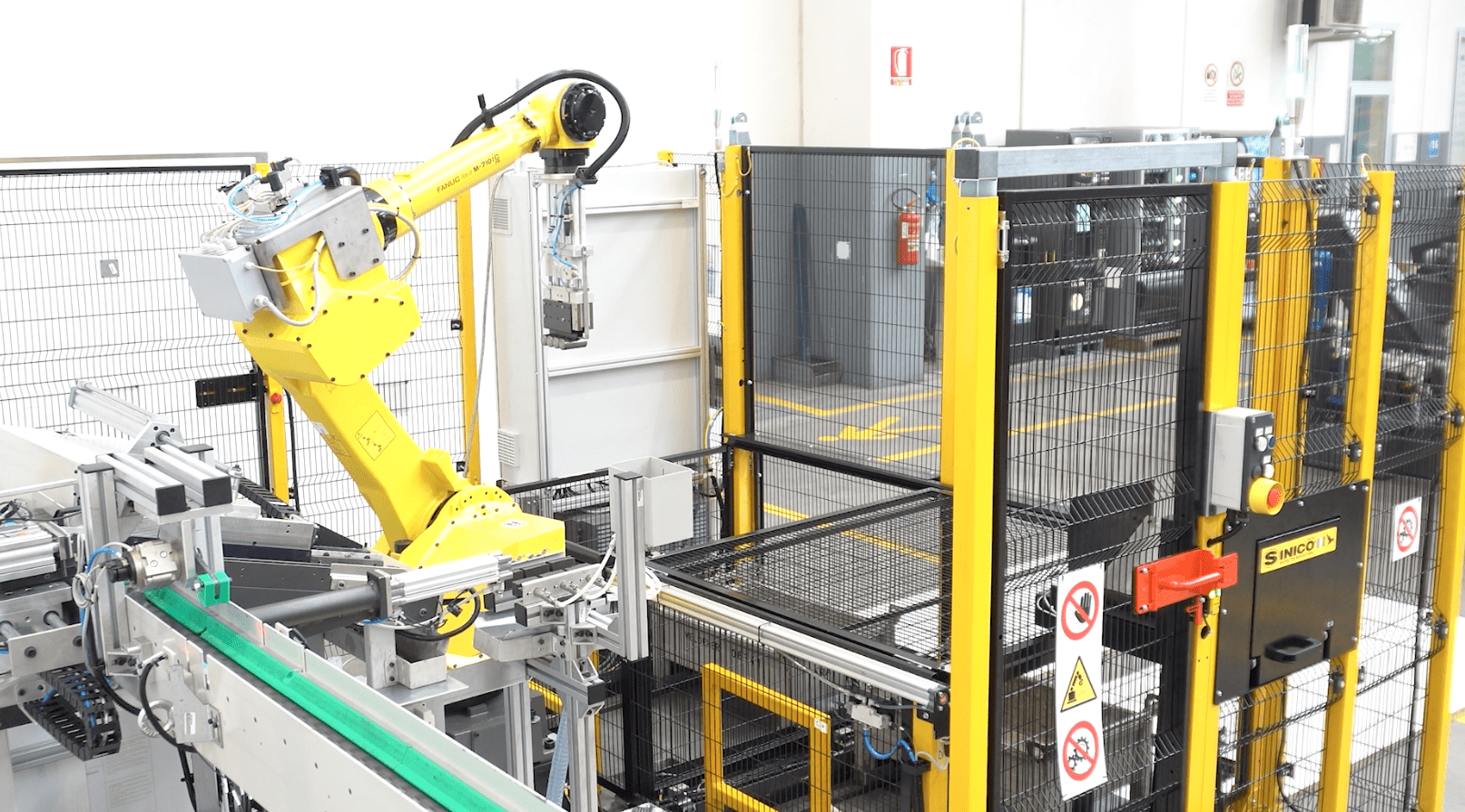

Sinico Service presents the RB70-S robot island, which is designed for unloading and palletising finished parts. It can be combined with all machines in the Sinico TOP and TAP lines and has a maximum lifting capacity of 70 kg.

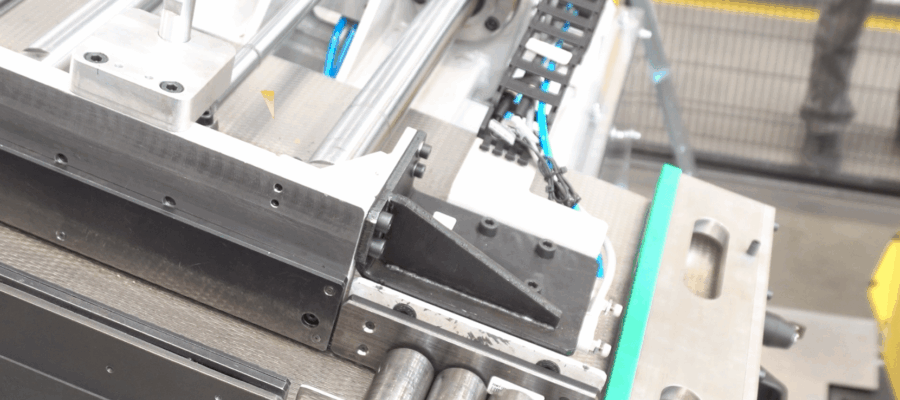

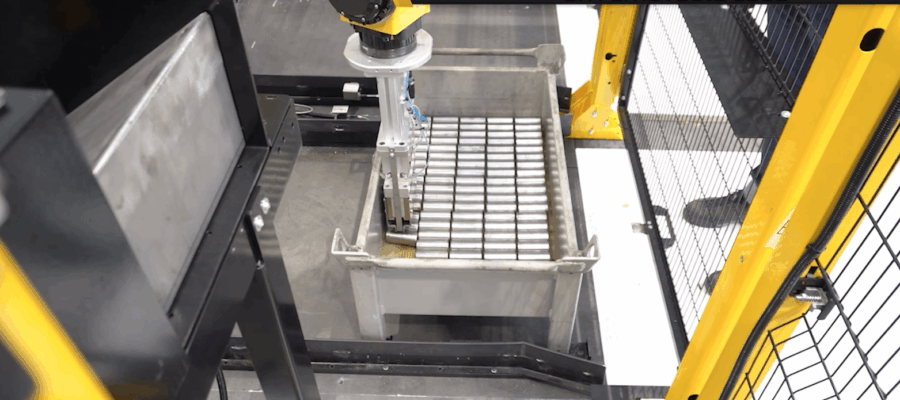

Equipped with a Fanuc robot, electronics and a magnetic gripper, the RB70-S can handle workpieces from the moment they are picked up until they are stored in crates, and back again, in a cycle time of 12 seconds. The robot can handle workpieces of different lengths in the same process through automatic adjustment, and recognise the dimensions of different crates.

The RB70-S can also be equipped with a workpiece oiling system.

The entire perimeter of the robot island is fully protected by a safety barrier and it is equipped with full CE integration.

The overall dimensions of the structure are 3500 x 4000 x 2500 mm (WxLxH).

Sinico Service Presents RB70-S Robotised Cell: Innovation for Unloading and Palletising Finished Parts

Sinico Service, a leading company in the mechanical and industrial automation sector, is pleased to present the RB70-S robot island. This advanced solution is designed for the unloading and palletising of finished parts. Designed to optimise production processes, the RB70-S integrates seamlessly with Sinico’s TOP and TAP machinery, enhancing the efficiency and safety of handling operations.

Advanced Capabilities and Performance

With an extraordinary lifting capacity of up to 70 kg, the RB70-S can handle parts of different sizes without compromising on precision or reliability. Thanks to Fanuc robotics technology, the RB70-S can handle the workpiece picking and positioning process extremely quickly. The entire cycle, from picking up the part to storing it in the case, takes only 12 seconds, enabling unparalleled productivity.

Flexibility and Precision

One of the distinctive features of the robot island is its operational flexibility. The system is able to automatically adapt to different lengths of parts to be picked, thanks to the automatic adjustment of the machine’s unloading device. Furthermore, the RB70-S is equipped with a system that recognises the size of the boxes to be loaded, ensuring accurate storage management and optimising space utilisation.

For companies working with parts that require lubrication treatment, the island can be equipped with a part oiling system, which ensures a complete and smooth handling of the production process.

Safety and CE regulations

Safety is one of Sinico Service’s key priorities, and the RB70-S is no exception. The island is surrounded by a safety barrier, minimising risks to operators. The RB70-S is also fully CE-compliant, meaning that all components and functions meet European safety and quality standards.

Design and Footprint

The RB70-S robot island has a compact and efficient design with the following dimensions: 3,500 mm in length, 4,000 mm in width, and 2,500 mm in height. These dimensions allow the system to be easily integrated into existing production lines while ensuring high performance and taking up minimal space.

Sinico Service continues to bring innovation to industrial automation solutions with the presentation of the RB70-S robot island, a system that offers superior performance, operational flexibility, and total safety. The possibility of combining this robot island with all machines in Sinico’s TOP and TAP lines makes it an ideal choice for companies looking to improve their productivity in a safe and intelligent way.

With a lifting capacity of up to 70 kg, a cycle speed of 12 seconds, and a range of advanced options such as an oiling system and case size recognition, the RB70-S robot island is the perfect solution for optimising the unloading and palletising process of finished parts.