General features

Overall dimensions [L x W x H] 9000 x 3000 x 2500 mm

Number of tools 2

Processing range

ø Min. of bend DN80 R114

ø Max. of curve DN200 R305

No. 2 ISO 50 spindles kW 15

No. 2 CNC longitudinal Z-axes

Caorle CL 90

Versatile and Powerful.

CNC machining centre with 90° unit for machining curved fittings equipped with an automatic workpiece loading/unloading system.

– one end-milling spindle

– one external chamfering spindle

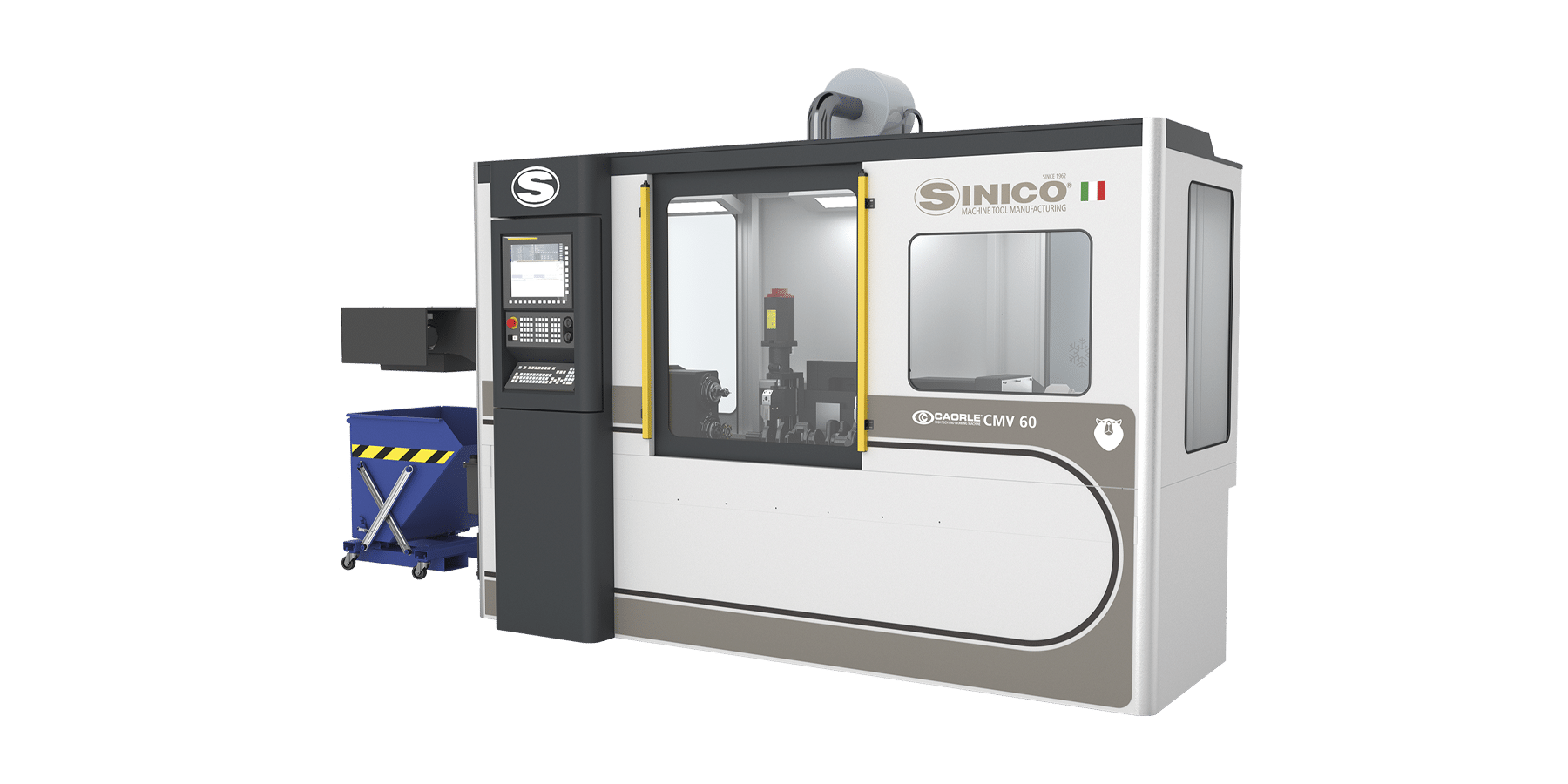

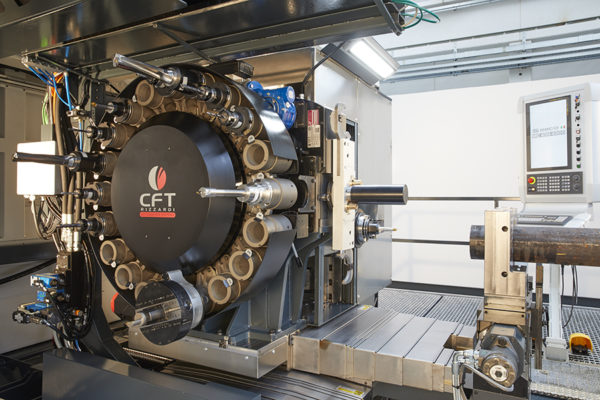

Caorle CMV 60

General features

Installed power 50 kW

Overall dimensions [L x W x H] 4780 x 2355 x 2150 mm

Processing range

Max. machining length – 1000 mm

Min. machining length – 50 mm

Min. clamping diameter – 10 mm

Max. clamping diameter – 100 mm

Min. milling diameter – 10 mm

Max. milling diameter – 80 mm

Max. drilling diameter – 20 mm

Max. drilling depth – 60 mm

Max. tapping capacity – 24 mm

Max. tapping depth – 60 mm

Spindle rotation speed min.-max – 15 – 1500 rpm

Spindle power – 5.5 – 11 kW

Spindle taper – HSK63 – ISO40

CNC Fanuc – Siemens

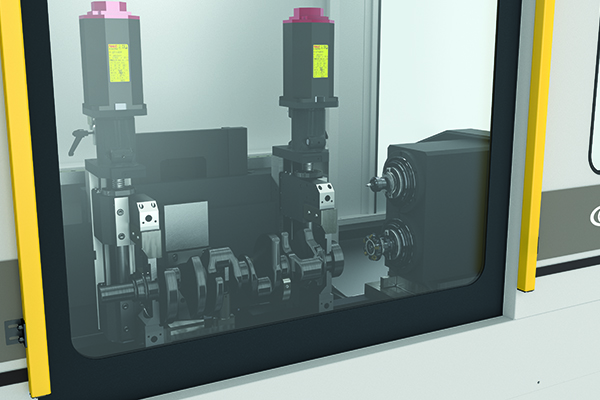

Caorle CMV 60

Versatile and Powerful.

The CMV60 model trimming center is a machine designed and built in various models that allows the machining of the ends of bars, tubes, molded parts and forging by means of 2 opposing heads each having a maximum of 3 spindles:

- a milling spindle

- a centering / drilling spindle

- a tapping spindle

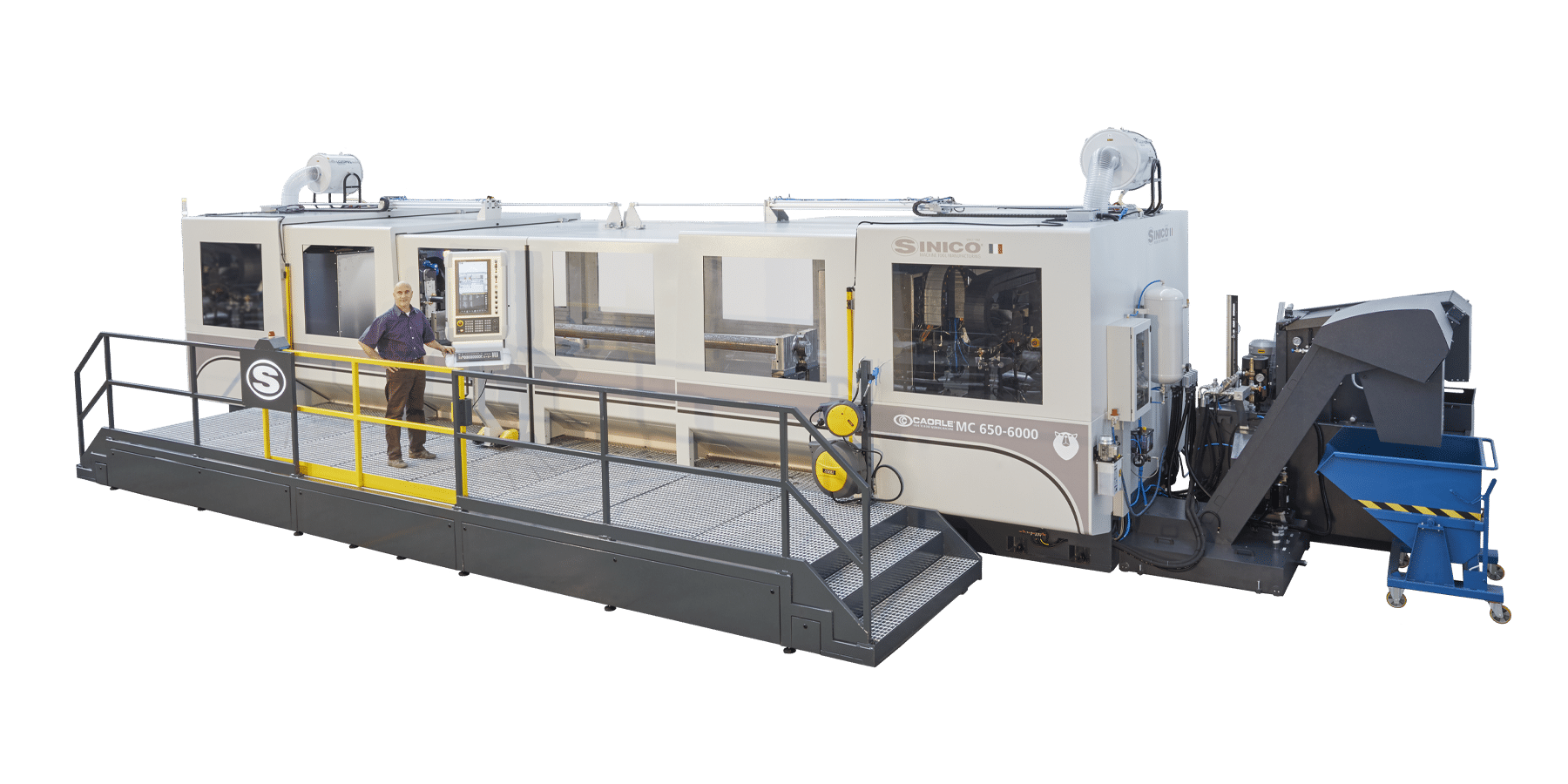

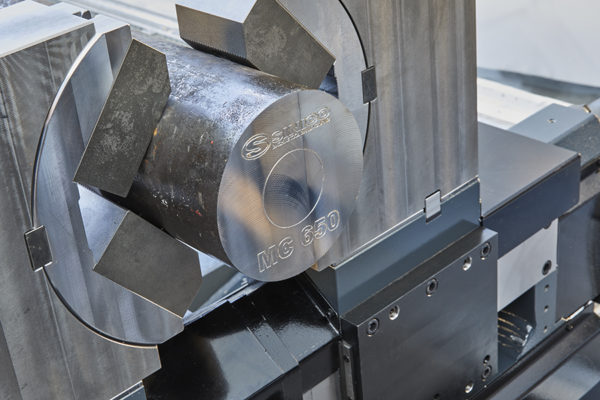

Caorle MC650

General features

Installed power – 110 kW

Overall dimensions [L x W x H] – 11500 x 4600 x 2900 mm

Number of tools – 10 – 20

Machining range

Transverse axis stroke ‘X’ – 400 mm

Vertical axis stroke ‘Y’ – 400 mm

Longitudinal axis travel ‘Z’ – 700 mm

Spindle speed min-max -100 – 5000 rpm

Spindle power – 22 kW/30kW

Spindle taper – ISO 50 – HSK 100

Min-max machining length – 200 – 6000 mm

Min-max machining diameter – 20 – 330 mm

Max. tapping size – M33

Number of tools in magazine – 10 – 20

Fanuc CNC

Caorle MC650

Versatile and Powerful.

Two ISO 50-spindle end machining machines, equipped with 3 + 3 CNC axes for heavy and precise machining

Horizontal machining centre for end machining, equipped with 2 opposed 3-axis operating units.

CNC machine capable of simultaneous end machining on tubes or bars.

Machine designed to be served by automatic loading system

It is capable of performing operations of

chamfering

facing

on-axis and off-axis drilling

deep drilling on and off-axis

threading

turning with static workpiece

boring

milling

profiling

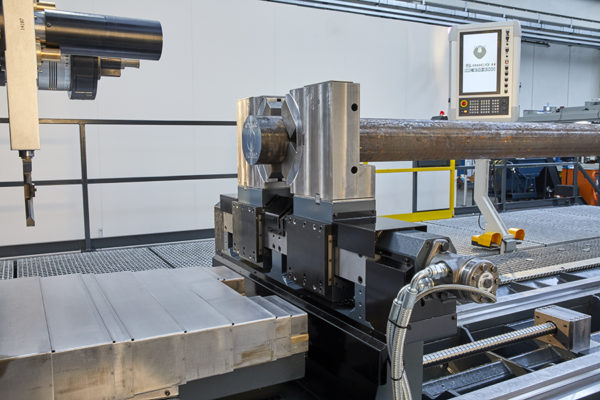

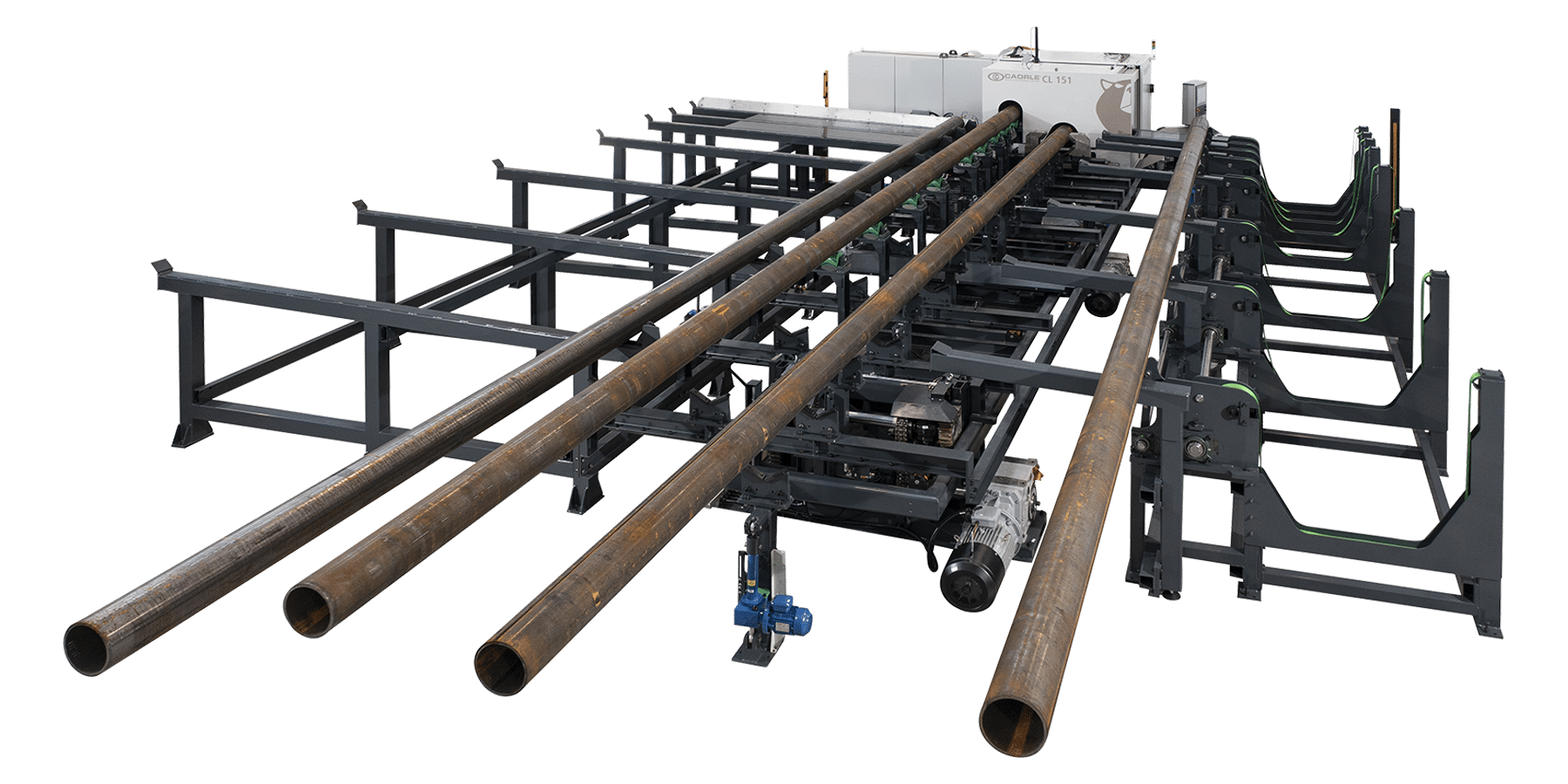

Caorle CL151

General features

Installed power – 90 kW

Number of tools – 2

Overall dimensions LxWxH – 4453 x 3012 x 2881 mm

Machining range

Z’ longitudinal axis stroke – 380 mm

Longitudinal axis travel ‘U’ – 120 mm

Spindle power – 22 kW

Min-max machining diameter – 60 – 275 mm

Spindle taper – D’Andrea radial head

Min-max machining length – 1000 – 12000 mm

CNC Fanuc – Siemens

Caorle CL151

Versatile and Powerful.

Machine for machining at the ends, equipped with bar loader/transfer device with pilgrim pitch for heavy bars e.g. micropiles.

It is capable of performing operations such as:

- threading

- tapping

- boring

- milling