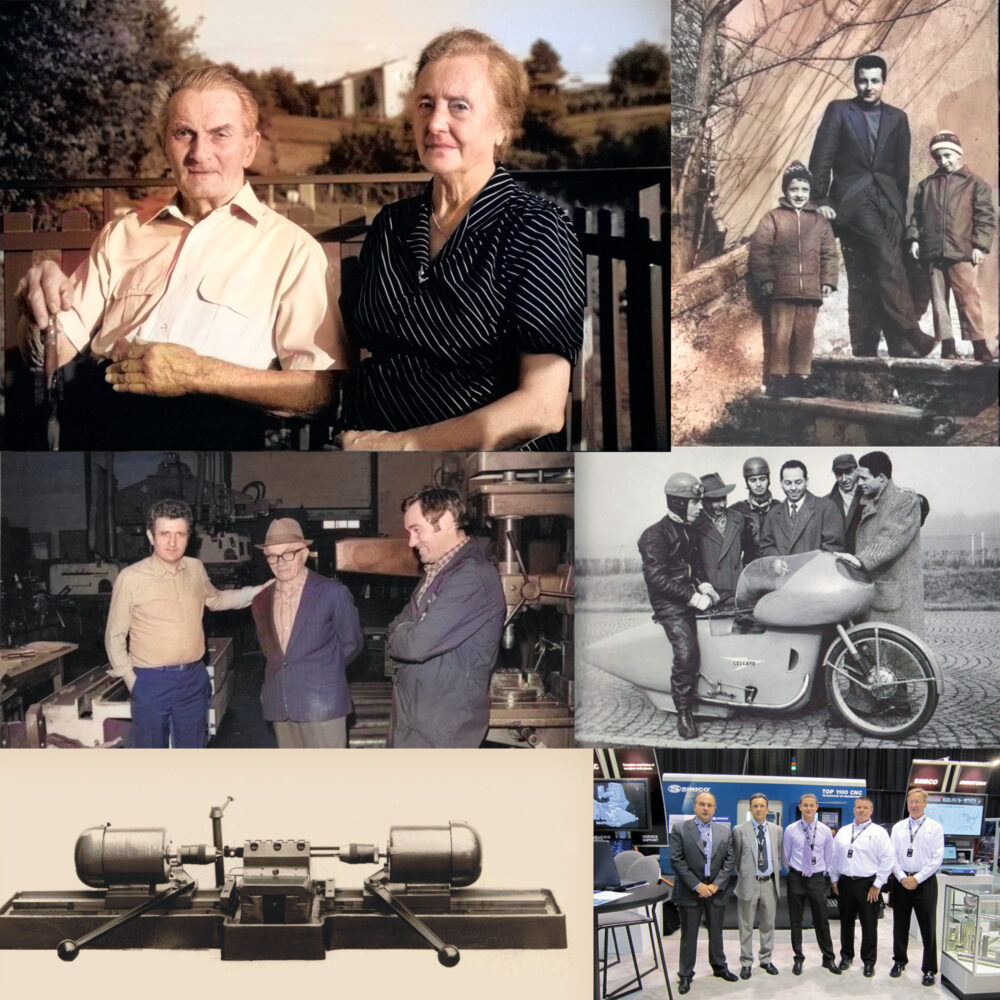

Pietro and Rosina Camerra, owners of the carpentry workshop that hosted Sinico’s first headquarters. Born before 1900, Pietro Camerra, a veteran of the two world wars, together with his wife Rosina, who passed away just a few years ago at almost 100 years of age, gave the first headquarters both space and encouragement, two critically essential ingredients in the company’s early days.

The idea

We want to be

A point of reference

300 pieces per second, this is the average production rate of SINICO machines worldwide. This is the prodigy on which we pride ourselves.

Where it all begins

The history of Sinico

Where it all began way back in 1962

The Philosophy

Our operating philosophy is born from the experience of the company’s founder, Egidio Sinico. This same philosophy continues to inspire his adult children, leaving a permanent imprint of devotion to work, product quality and correct market placement. The experience acquired in more than 50 years of business serves as a valuable guide on how to address an increasingly variable and flexible market.

A team of experts always on the lookout for innovative solutions and a cutting-edge machine shop: this is the environment in which we have forever nurtured our passion for the development of technologically advanced works, tailored to suit the most demanding needs.

The Men

Igino Camerra, son of Pietro and Rosina, is one of the company’s founding partners. Born in 1933, a great enthusiast and keen observer of mechanical evolution, he was always very dedicated to producing the precision parts making up the machine.

He is pictured here on a mountain hike with his two grandsons, Alessandro and Giancarlo Sinico, a few years after the company was established. Alessandro is the current owner of the company, wholly run by the family.

The other two founding partners of Sinico, on the left, Egidio Sinico, born in 1931, and on the right, Bortolo Groppo, born in 1938. Egidio Sinico mainly dealt with the company’s management, while Bortolo Groppo was responsible for machine finalisation and testing with the client and at their premises. In the middle, Domenico Bosa, also part of the family and with a long background in mechanical engineering. He often visited the company to give advice, and above all, great encouragement. Egidio Sinico, in 1994, a few years after his two partners had retired, left the company to his sons Alessandro and Giancarlo.

Alessandro Sinico

Alessandro Sinico, born in 1960, has now been working in the company for thirty years. For over 10 years he has had the opportunity to accumulate experience, in the most practical sense of the word, through a path that has taken him through every single production department, including cleaning. For more than 20 years, he has been managing director of the company, assisted by a splendid team of collaborators, capable of making this activity and life experience exciting.

He is pictured here taking an early morning stroll along one of the magnificent dirt roads at the foot of Romeo and Juliet’s castles. He has written this story with a feeling of immense gratitude towards his collaborators now and then, and with equal gratitude towards those customers who have made Sinico their first choice over the last half century.

60 years of innovation

Sinico before

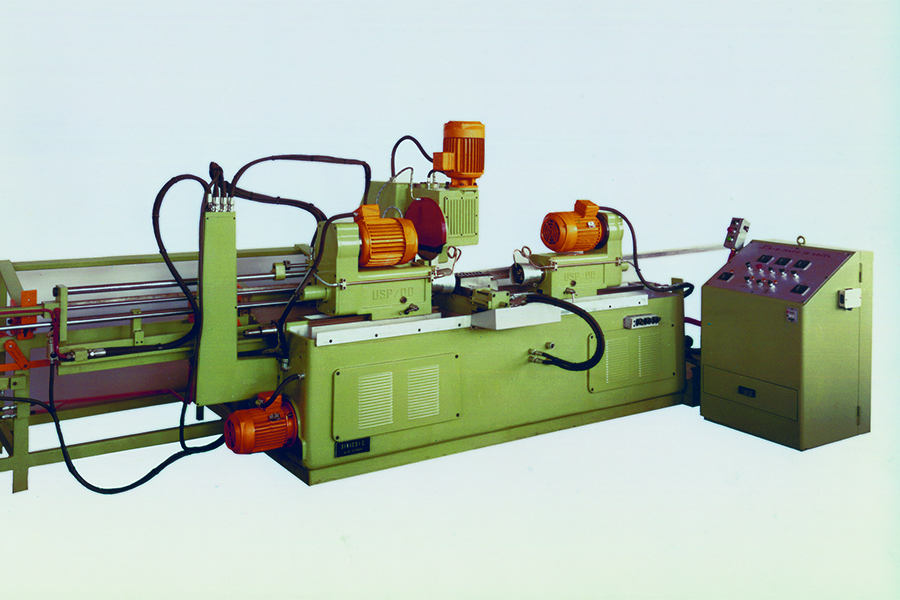

In the second half of the 1970s, both the ‘TC’ and ‘TR’ models continued their evolution. The TC model is fully automated and completed with an automatic bar loader that allows the operator to load a complete bundle while minimising bar handling.

Sinico today

In December 2017, the first TOP1100 CNC plus was born, soon to become Sinico’s tip product.

What we are today

11,000 Mq

Our operators work in a heated and conditioned space, with all the necessary facilities for their well-being

95 employees

We are also present in America with a sales office in Cleveland, Ohio

We invest in the future

Sinico today invests in technology, innovation and a young, dynamic staff supported by our most experienced workers

What does it look like today?

Our assembly line

Positioning production sectors

The construction of our machines requires precise organization.

Station1

Basement arrival and machine assembly.

Station2

Customer-required loader assembly.

Station3

Wiring electrical part and control panel setup.

Station4

Functional testing and acceptance with customer presence.

Workshop1

Finishing and inspection of internally produced parts.

Workshop2

Lathe department for production from drawing of parts.

Officina3

Heavy machining section for machine bases and bodies.

Workshop4

Preparation of parts for processing.