General features

Machine weight – 12000 kg

Installed power – 80 kW

Machining range

Diameter – 10/55 mm

Length: 10-200mm – length control station with independent good/scrap selection

Bar length capacity – 2500 – 6000 mm / beam bar stock

Operating unit – HSK 50

Motor power – 5.5 kW

Spindle revolutions – 400 – 4500 rpm

Troncatric

Motor power – 5.5/7.5 kW

Blade disc rotation speed – 360 – 300 rpm

Blade disc diameter – 285/350 mm

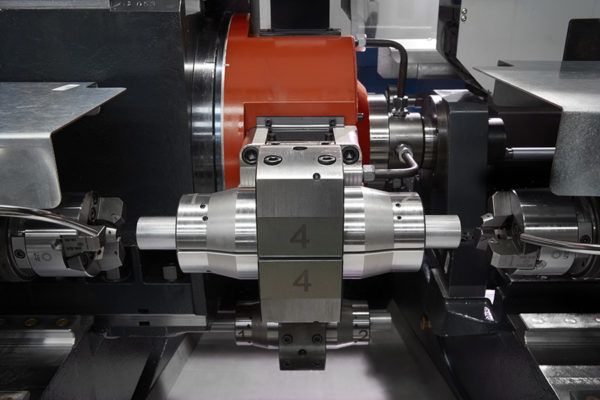

TOP 1100 R2 CNC

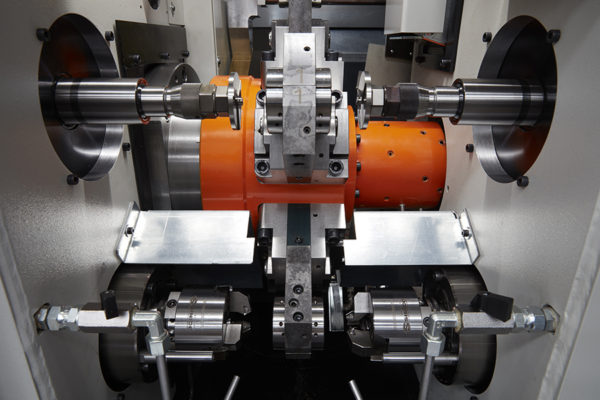

Automatic CNC machine for cutting to length and machining at the ends.

Transfer machine with horizontal axis table for cutting and machining tube and bar ends and dimensional inspection.

CNC machine with high productivity, up to 2750 pieces/hour, designed for machining small parts: bar diameter from 10 to 55 mm per tube, 10/30 per bar, finished part length up to 200 mm.

Excellent performance for all types of machining

It is capable of performing operations such as:

Chamfering – Facing – Drilling – Boring

General features

Machine weight – 16000 Kg

Installed power – 100 kW

Machining range

Diameter – Max 81 mm pipe – 40 mm bar

Workpiece length – 10-350 mm

Bar length capacity – 3000 – 6000 mm / beam bar stock

Operating unit – HSK 63

Spindle revolutions – 450 – 4000 rpm

Numerical control – Siemens 840 D

Cut-off machine

Motor power – 11 kW

Blade disc rotation speed – 40 – 260 rpm

Blade disc diameter – 315 – 450 mm

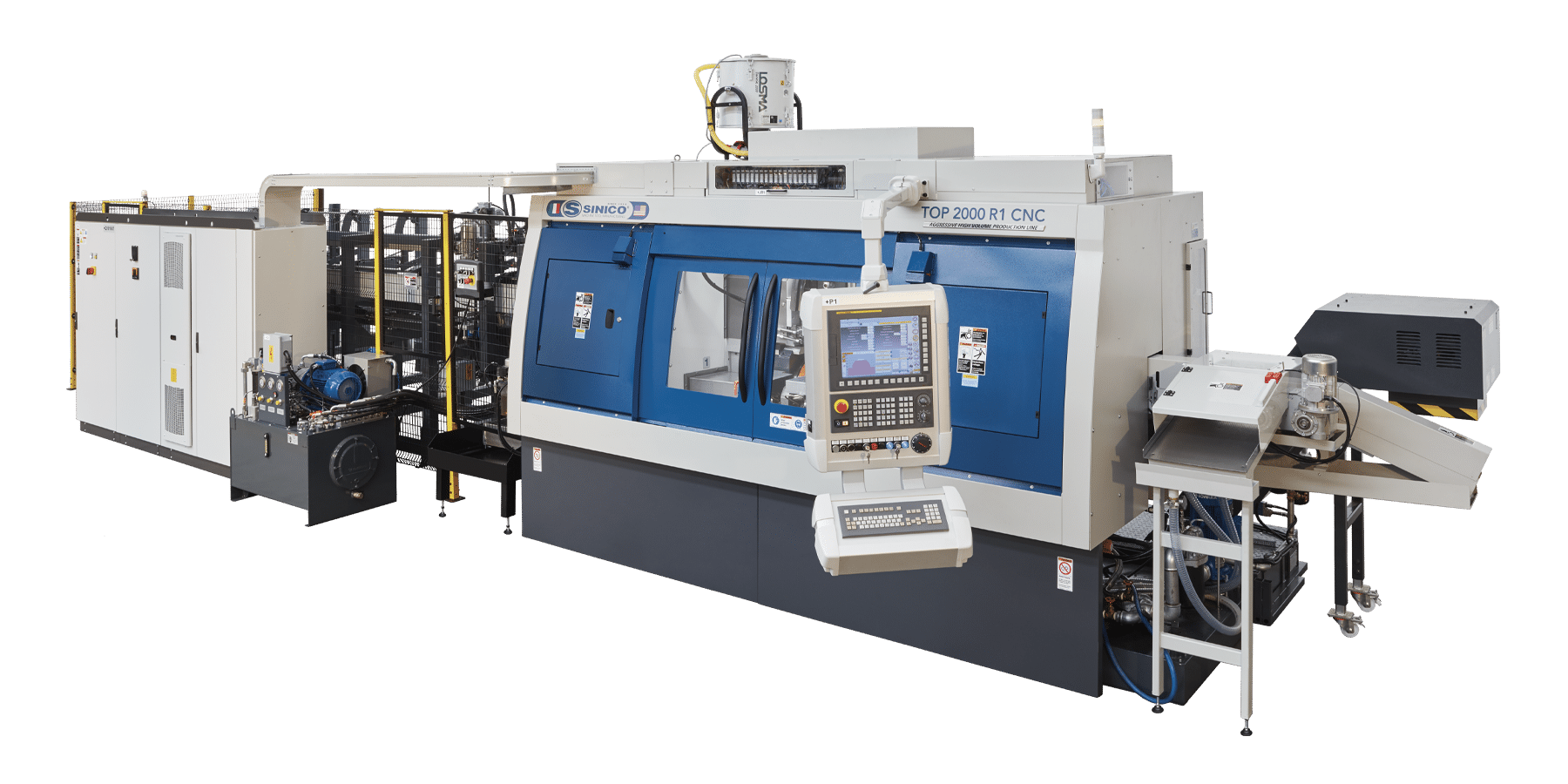

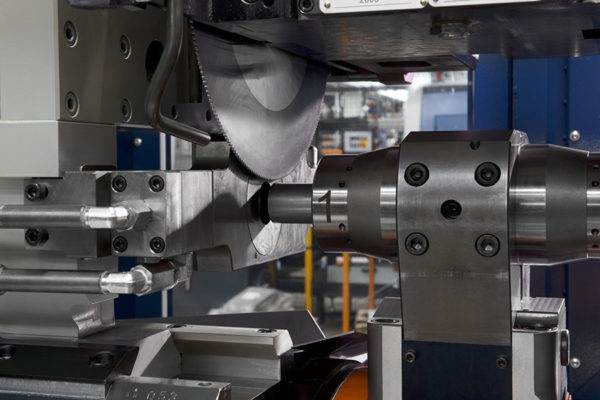

Top 2000 R1 CNC

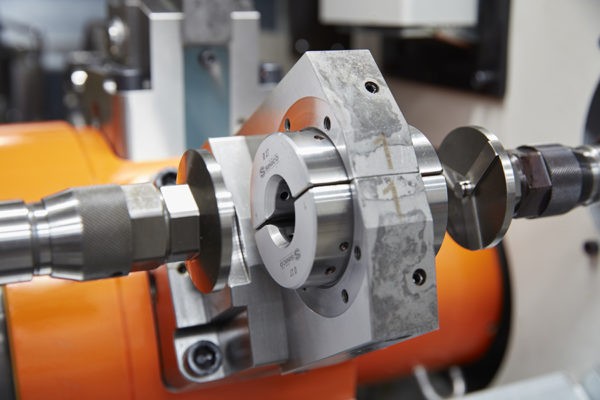

Automatic CNC machine for cutting to length and machining at the ends.

Transfer machine with horizontal axis table for cutting and machining tube and bar ends.

Flexible and highly customizable CNC machine. It guarantees high productivity, up to 2500 parts/hour, and is designed for machining small to large parts.

Maximum versatility in tube and bar machining

It is capable of performing operations such as:

Chamfering – Facing – Longitudinal drilling – Threading – Boring.

General features

Machine weight – 10000 kg

Installed power – 71.7 kW

Machining range

Diameter – Max 90 mm tubes – 40 mm bar

Workpiece length – 15-350 mm

Bar length capacity – 3000 – 6500 mm/bar magazine

Operating unit – HSK 63

Spindle speed – 200 – 3000 rpm

Numerical control – NUM

Cut-off machine

Motor power – 9 kW

Blade disc rotation speed – 35 – 230 rpm

Blade disc diameter – 350 – 450 mm

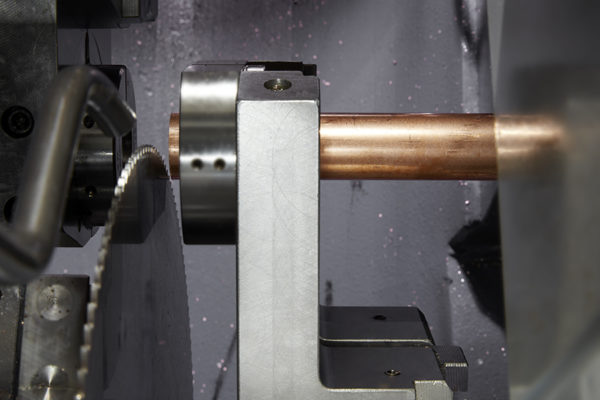

Top 2000 R1 CNC

Automatic CNC machine for cutting to length and machining at the ends.

Transfer machine with horizontal axis table for cutting and machining tube and bar ends.

Flexible and highly customizable CNC machine. It guarantees high productivity, up to 2500 parts/hour, and is designed for machining small to large parts.

Maximum versatility in tube and bar machining

It is capable of performing operations such as:

Chamfering – Facing – Longitudinal drilling – Threading – Boring.