Threading is the machining process by which a thread is created, a helical groove on a workpiece that tends to be cylindrical. Depending on whether the machining operation is carried out on the external or internal surface of the workpiece, the object is called a screw or female screw, respectively.

This mechanical construction is very commonly used as it represents a very efficient fastening system in many sectors. There are numerous types of threads, each with distinctive characteristics and functions. In this article we will analyse the main ones and other curiosities.

Main elements of threading

The elements which go to define the characteristics and peculiarities of the various types of existing threads are:

- Profile shape: This term is used to identify the geometric shape obtained from the thread section. Analysing this in more detail, three types of profile can be distinguished. Firstly there is the ideal profile, which is the geometric reference shape. The second is the nominal profile, which is distinguished from the previous one by the possible presence of rounding or truncations. Finally there is the execution profile, which is the one actually realised;

- Pitch: The pitch represents the distance between two consecutive ridges. It is proportional to the height of the thread and indicates how much feed there is with each complete turn of the screw in the female screw;

- Nominal diameter: The nominal diameter of the thread is generally the external diameter of the screw which coincides, except in some cases, with the internal diameter of the nut;

- Direction of screwing: The direction of screwing is the direction in which the thread helix develops. Depending on this direction, the thread is said to be right-handed if clockwise, and left-handed if anti-clockwise;

- Number of principles: This term is used when there are several threads side by side. This choice is made in order to obtain a quick coupling without, however, having a decrease in the resistance of the screw. In this case there will be a mismatch between the pitch of the profile and that of the thread.

Classification

The main classification of thread types is based on their profile shape and distinguishes two macro categories:

- Triangular profile threads: this group includes all those threads that are measured in millimetres and fall under the ISO classification, those that are not measured in millimetres such as Whitworth and Gas threading, and finally threadings for wood screws.

- Non-triangular profile threads. This category is represented by trapezoidal and sawtooth threads. As the name suggests, the geometric form of reference is a trapezoid. This provides greater ease of threading and robustness. In the second case, on the other hand, there is a special thread with an asymmetrical trapezoid. Such a thread is generally used when there are large constant directional and directional forces.

Once we have distinguished these, let us take a look at the main threads that are most common in the world of mechanics.

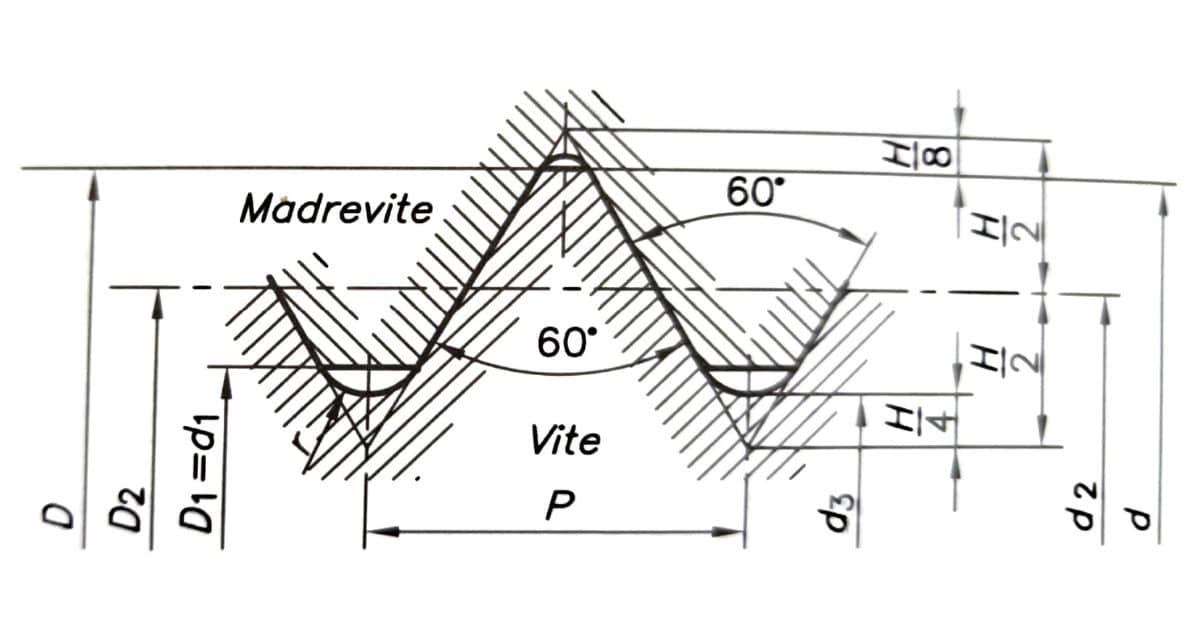

ISO Metric Threading

The ISO thread is the standard recognised by the International Organisation for Standardisation and has an ideal profile of an equilateral triangle with an angle of 60°. Threads of this type are always indicated by a letter M followed by the nominal diameter and have a helix on the right. If, on the other hand, a left-handed helix is required, it must be specifically marked LH (Left Hand).

Its widespread use can be explained by its characteristics. In fact, the thread ridges are completely flattened, so the two threads only come into contact with the flanks of the thread itself, while the ridges have appreciable play. Therefore, although this type of thread is not pressure fluid-tight, the non-interference between the parts makes construction and assembly easy.

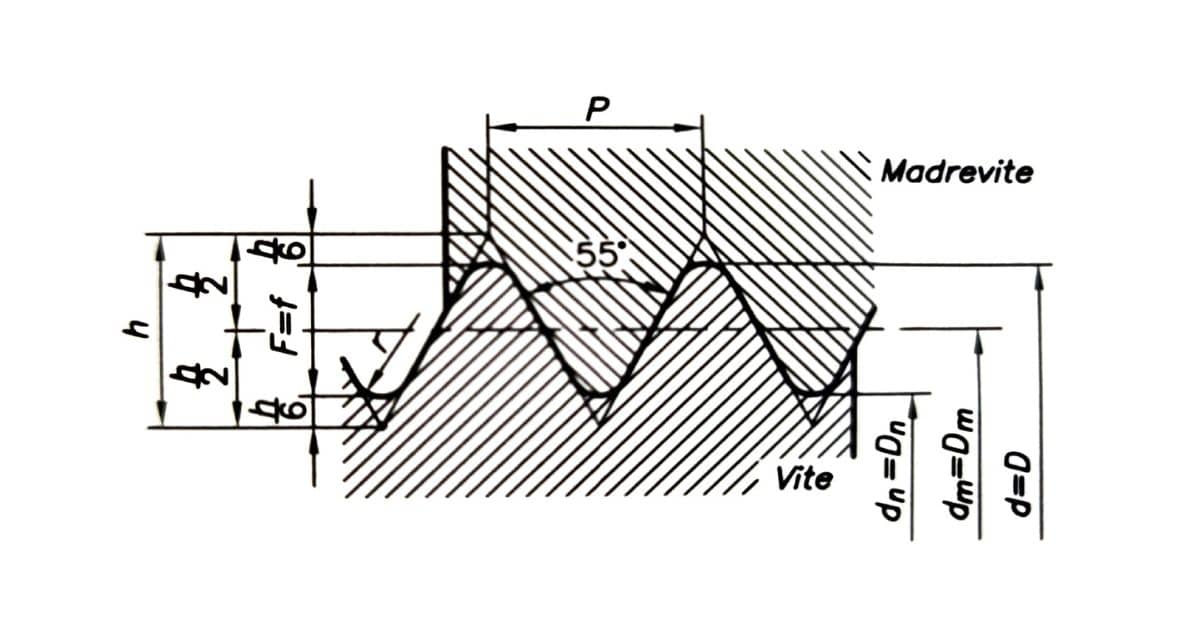

Whitworth Thread

This thread is identified by W the nominal diameter in inches or fractions thereof. It is very similar to the ISO thread but differs substantially in the presence of a vertex angle of 55 and has a rounded radius of h/6 on both the ridges and the bottom. In this case, therefore, the contact between the fillets is on both flanks and ridges.

The typical characteristic of this machining is the coarseness of the thread in relation to the thread diameter and therefore a higher probability of unscrewing, especially in the event of vibration. This has led some Anglo-Saxon countries to adopt the metric one.

Gas Threading

The Gas thread has similar characteristics to the Whitworth thread, but has a much finer pitch. For this reason it is able to guarantee a greater tightness and is widely used in the connection of pipes for conducting fluids, even at high pressure. In this case, conventional nominal diameter refers to the theoretical diameter of the pipe on which the thread is made.

Special Threading

To complete this overview of the various types of threads, let us now look at others that are less common than the previous ones, but still interesting.

- Edison thread: features a wave profile, mainly used for electrical connections;

- Lowenherz thread: used on measuring and optical instruments, this thread has a symmetrical triangular profile with sharp edges on both the ridges and the bottom;

- UST: the Unified thread has a triangular profile with a chamfered ridge and flush bottom;

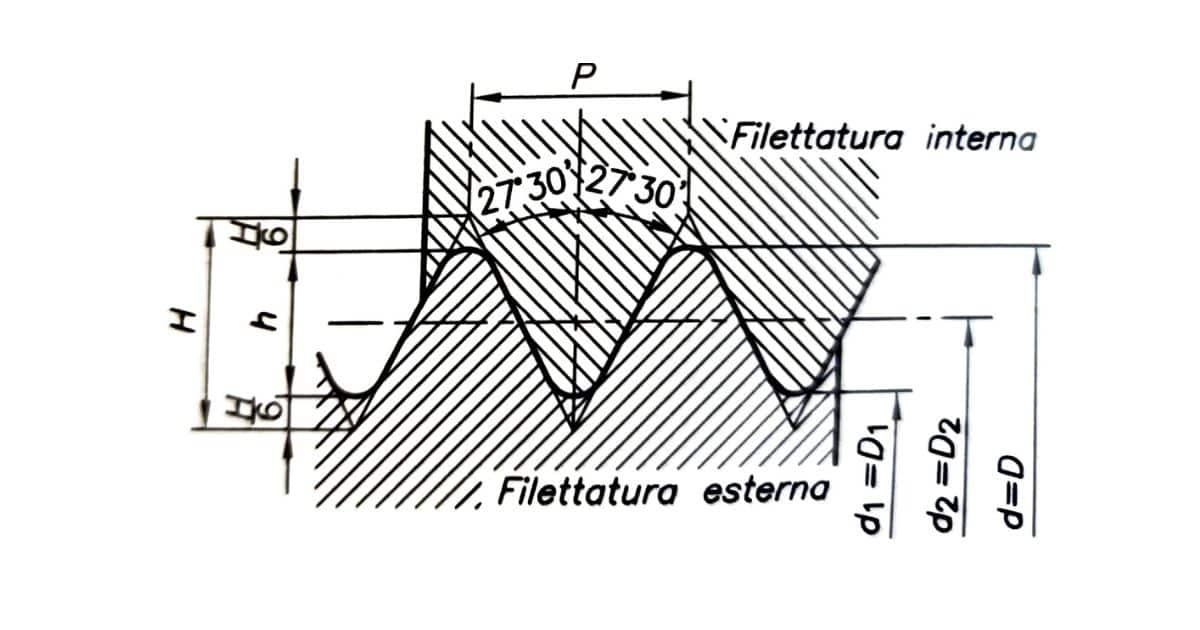

- British Association (BA): threading with a triangular profile with connected ridge and bottom and internal angular walls of 47°30′;

- American Standard: this type of thread has a triangular profile with chamfered ridge and bottom and internal walls angled at 60°.

- PG thread: this type was created in Germany from the German term Panzergewinde. Its peculiarity is that it has a profile angle of 80° and therefore a shallow depth, ideal for machining pipes with minimal thickness, such as those carrying electrical conductors.

Method of manufacture

Mechanical threading can be produced by various manufacturing methods. Among the various techniques for metal working, those that can be used to make these products are:

- Casting;

- Stamping;

- The chip removal;

- Rolling.

In each case, this machining involves the forced screwing of tools onto the surface to be machined. Tools for making screws are called tool dies, while those for making the nut are called taps.

Threading Machines

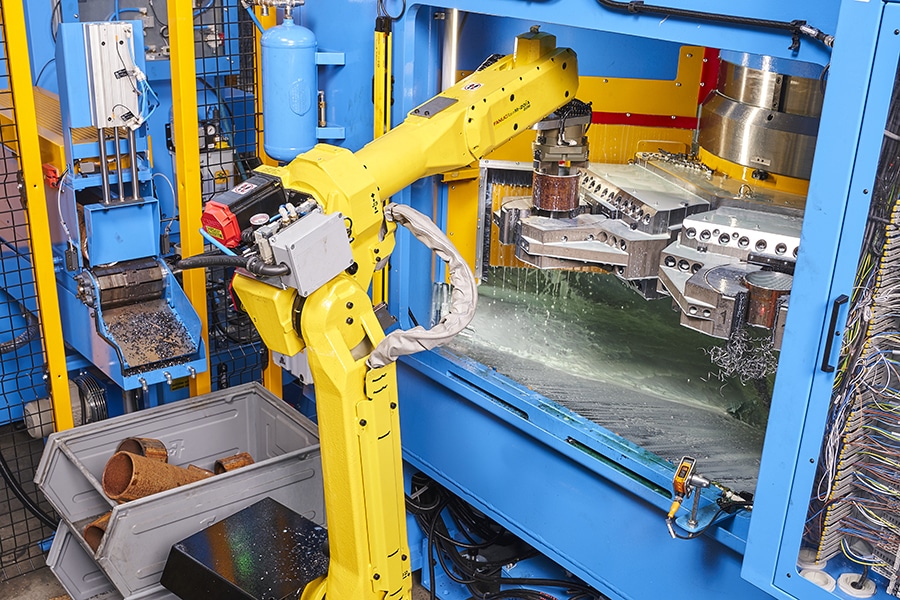

Thread cutting for metal parts must necessarily be carried out with specially designed machines. Only these types of machines are able to impart such a force on the material.

Depending on the production level, special machines are used. For high volumes, for example, individual machine tools are not sufficient, but special CNC machines designed to organise and make all production steps efficient.

This is the case with Sinico machines, which specialise in CNC cutting and threading of metal components. Over the years, these machines have enabled numerous manufacturers of nipples, fittings and threaded bushings to minimise machining costs and times. They are designed on the basis of our customers’ needs, thus understanding the requirements and providing the best solutions.