Pipe Nipples are one of the fundamental mechanical constructions for hydraulic systems and pipelines. These are fittings made from tubular sections with threads on one or both ends. These components are widely used to connect and fasten pipes together.

Function, materials and fields of application

Thanks to their threaded ends, nipples provide a connection between pipe sections, thus forming pipes for different types of fluids. A direct consequence of this function is that they are subjected to numerous and often prolonged solicitations. It is therefore necessary that they are made of materials that guarantee adequate mechanical strength and high corrosion resistance. The most commonly used material is therefore stainless steel, but nipples can also be found in bronze, aluminium and other polymeric materials.

La resistenza e la semplicità di utilizzo li rendono componenti operativi importanti nei settori più disparati come:

- Oil & Gas industry;

- Chemical processing industry;

- Petrochemical industry;

- Pharmaceutical industry;

- Machine building industry;

- Semiconductor industry;

- Shipbuilding industry;

- Paper & Pulp industry;

- Food & beverage industry.

Types of nipples

To meet different needs, numerous types have been produced, varying in size, diameter and the type of threading applied to them. The most common are:

- Barrel pipe nipple: this type of nipple has a tapered NPT thread on both ends and the central section is unthreaded;

- T.O.E. pipe nipple: In this case we have a nipple that has a thread on only one of the two sides, usually used as feet for oil containers;

- Weld pipe nipple: Similar to the previous type, but with the difference that there is a chamfer on the unthreaded end, required to facilitate subsequent welding. Ideal for use in extreme conditions such as vibrations, pressure fluctuations and temperature changes;

- Close pipe Nipple: this nipple is characterised by the absence of the unthreaded section, so once two female fittings are screwed onto it, only a small part will be visible;

- Shoulder pipe nipple: a fitting similar to the close nipple, but with the difference of being longer and having the unthreaded section, albeit minimal;

- Hexagonal pipe nipple: As the name of this nipple suggests, its distinguishing feature is that it has a hexagonal unthreaded intermediate section. It allows for greater grip when using a spanner;

- Right-Left hand pipe nipple: this nipple has the distinctive feature of having a right-hand thread at one end and a left-hand thread at the other. It is mainly used for gas pipes and pipelines;

- Swage pipe nipple: as the name suggests, this type of nipple is designed to bring the flow of a fluid from a pipe of one size to another pipe of a different size. Within this category there are two types depending on whether the two parts of the nipple are aligned or not. In the first case they are called concentric and are mainly used in vertical pipes. In the second case, on the other hand, we speak of eccentric fittings, which are used for horizontal pipelines. In some cases eccentric reductions are preferred to concentric ones, as they allow a better flow of the fluid;

- Grooved pipe nipple: as the name indicates, the distinctive feature is the presence of a groove, commonly used in commercial, industrial and mining applications.

Production technologies

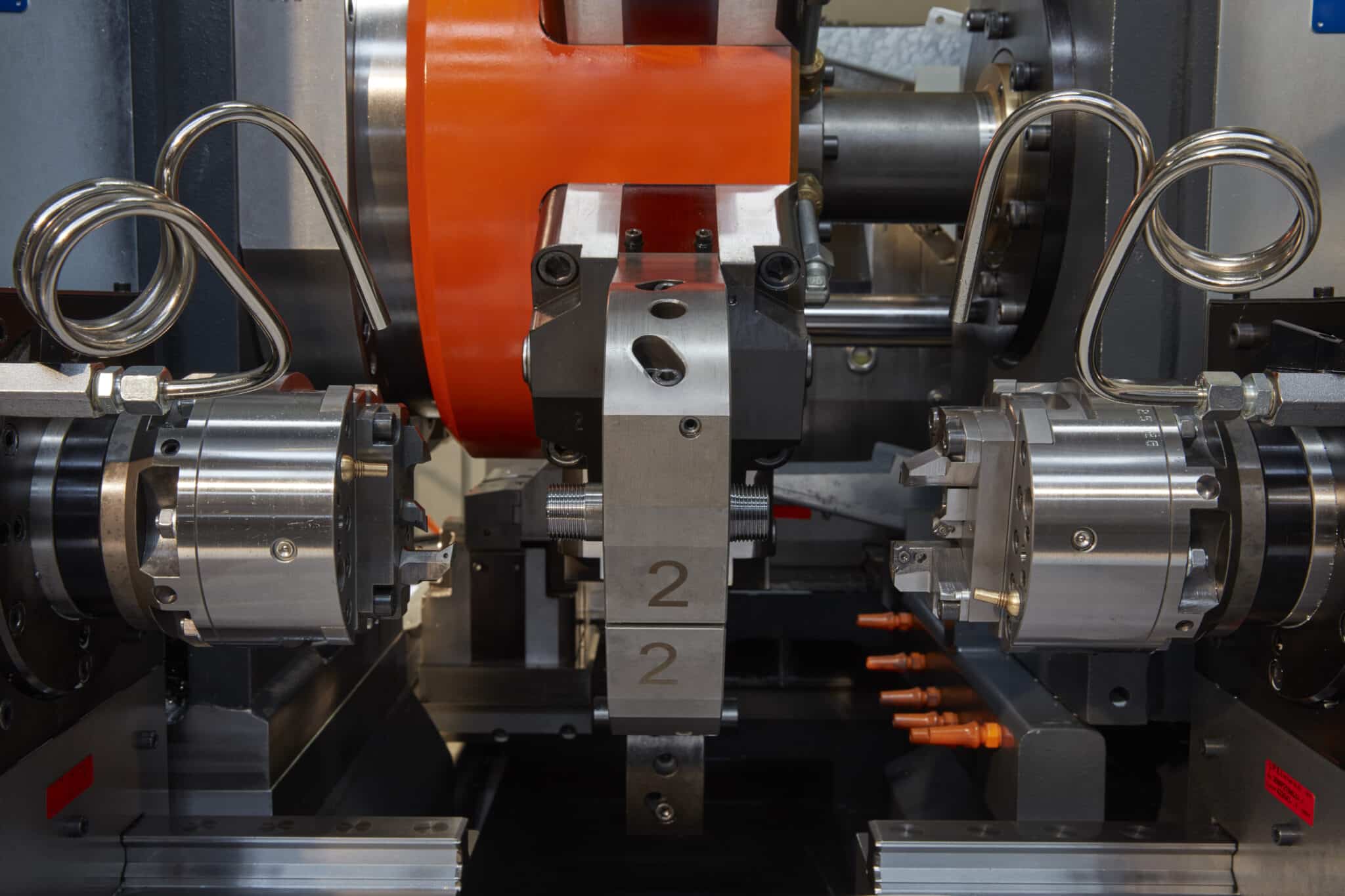

For the production of nipples, threading machines are used, using selective chip removal. Due to the large quantity of parts that is generally required, special lines are used for the mass production of nipples. These automatic machines are in fact able to sequentially handle all the operations necessary to arrive at the finished product, while keeping production costs low.

Sinico machines are ideal for this type of machining and are in fact used for the production of nipples in numerous plants around the world. They are an efficient solution for the production of most types of nipples described above. Each machine is designed on the basis of the nipple to be produced, taking into account all specific customer requirements. In this way, we can provide the best process to achieve fast, precise and economical production.

The most appropriate line for the production of nipples is the Top, as it is equipped with an integrated cutting unit, together with an automatic loader. Thanks to this, it is possible to carry out all operations, from cutting to the finished product. An example of our optimisation capability is a Top 1100 Plus with 6 operating units. it can perform the entire process in just under 14″.

In this video you can see this line at work and if you have any curiosity do not hesitate to contact us.