The term transfer machines is the name commonly used for automatic workpiece transfer machines. Their main characteristic is that several functions performed by separate machines are combined in a single operating unit. This is achieved by unifying the loading and transfer operations of the pieces in a single production line.

Each transfer machine is made up of a series of work stations that simultaneously transport and process the pieces without interruption. The resulting automation means that errors associated with repositioning the workpiece are not affected and high standards of precision and repeatability are guaranteed.

Main features

This type of machines optimises each phase of the manufacturing process, thus producing a high quantity of parts at a reasonable price. In fact, the programming of the numerical control reduces the waste of time and resources during the various operations.

Thanks to these features, transfer machines are the ideal solution for many sectors where there is a need to produce large quantities of standardised products, such as the production of fittings and valves used in the automotive sector.

Sinico TAP, the new frontier of Transfer

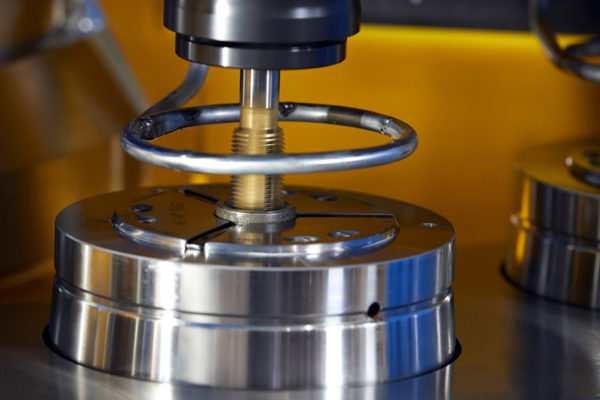

We have developed an innovative solution by creating a CNC transfer line specialized in automatic tapping: the Tap Line. The tapping operation is made fast and precise thanks to the introduction of the new Sinico snap-on male.

This line includes models capable of adapting to production requirements. Depending on the customer’s needs, our technicians can find the configuration of each station to achieve the most efficient solution.

Sinico offers many customisation possibilities for each machine. For example, the line transfer machines can be integrated with modern robotic arm feeders or the Beaver 200 HD automatic saw.

In addition, for additional machining in addition to tapping, these machines can also be combined with the machine tools of the Top Line to create a complete production line and further increase production efficiency.